When manufacturing special-shaped carbon fiber parts for automobiles, how to accurately control the direction and order of the plying of carbon fiber prepreg to meet the strength and performance requirements of different parts of the special-shaped parts?

In the complex structure of the automotive industry, special-shaped carbon fiber parts are like precision gears, widely and deeply embedded in multiple key components, playing an irreplaceable role.

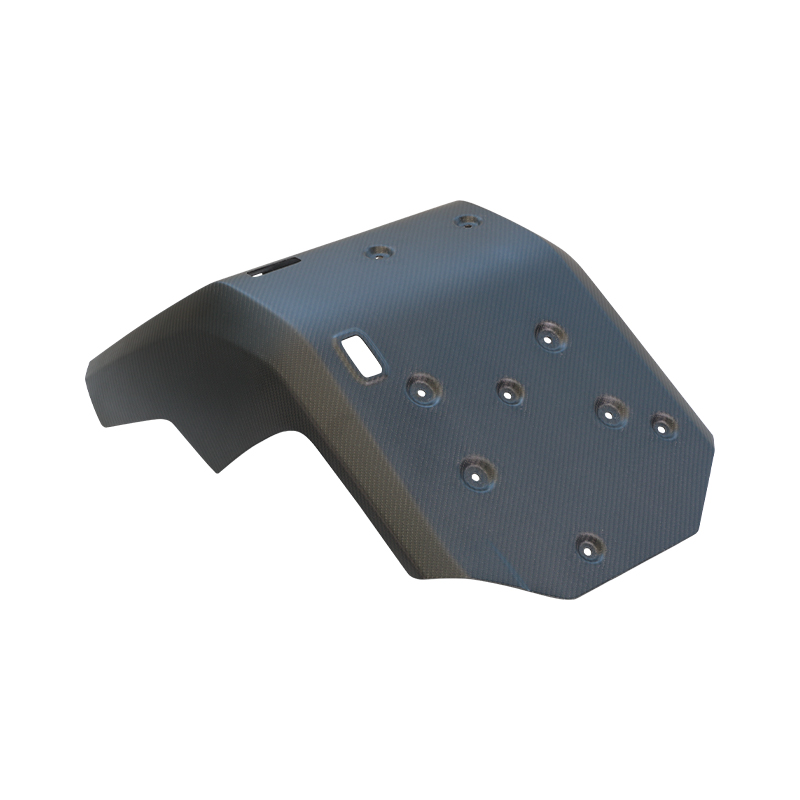

(I) Body Coverings

As the direct presentation part of the appearance of the car, the choice of material for the body covering not only affects the overall weight of the vehicle, but also has a profound impact on the appearance texture and aerodynamic performance. The carbon fiber body coverings produced by Dongli New Materials give full play to the advantages of carbon fiber materials, greatly reducing the weight while improving the appearance of the vehicle. Its unique manufacturing process gives the body coverings excellent surface flatness and glossiness, adding a sense of technology and modernity to the appearance of the vehicle. And by optimizing the aerodynamic design, the drag coefficient is effectively reduced, thereby improving the vehicle's cruising range and driving stability.

(II) Chassis structural parts

Chassis structural parts are the "skeleton" of the car, and their rigidity and stability directly determine the handling performance of the vehicle. The carbon fiber special-shaped chassis structural parts developed and manufactured by Dongli New Materials significantly improve the overall rigidity of the chassis and effectively reduce the vibration and deformation of the vehicle during driving. This not only brings a smoother and more precise driving experience to the driver, but also enhances the safety of the vehicle under high-speed driving and complex road conditions.

(III) Interior parts

In the field of automotive interiors, carbon fiber products create a unique atmosphere for the interior space. On the one hand, the lightweight characteristics of carbon fiber help to further reduce the weight of the car body and improve the overall performance of the vehicle; on the other hand, its unique texture and texture can add a sense of technology and luxury to the interior of the car. The application of carbon fiber products in interior parts such as the center console and seats not only improves the quality of the interior, but also brings a more comfortable and personalized driving experience to passengers.

II. The core position of precise control of prepreg layering

In the complex process chain of special-shaped parts in the carbon fiber automotive industry, precise control of the direction and order of the plying of carbon fiber prepreg is undoubtedly the most critical link, just like the heart in the human body, playing a decisive role. As a material made of carbon fiber fabric or fiber unidirectional arrangement and resin impregnation and curing, the plying method of carbon fiber prepreg is like the brick and stone stacking method in construction, which directly determines the performance of the final special-shaped parts.

(I) Principle basis

The reason why carbon fiber has high strength characteristics lies in its unique microstructure. Each carbon fiber filament is like a high-strength "rebar" in the microscopic world, with extremely high axial strength. When these carbon fiber filaments are arranged in order in a specific direction and tightly bonded together by resin, it is like pouring countless high-strength "rebars" into a whole with concrete, forming a composite material with specific mechanical properties. In the actual use of special-shaped parts, the types and sizes of stresses borne by different parts vary greatly. Taking the car body as an example, some parts of the car body, such as the door frame, may be mainly subjected to tensile stress in daily use because the door will be pulled when it is opened and closed; while the roof part may be subjected to bending stress in extreme cases such as the vehicle rolling over. In order to make the special-shaped parts have the corresponding strength and performance in each part to cope with different stresses, the ply direction and sequence of carbon fiber prepreg must be accurately designed according to the detailed stress distribution.

(II) Actual operation process

Structural analysis and design

Before officially entering the manufacturing stage, the use conditions of the special-shaped parts are first simulated and analyzed in a comprehensive and detailed manner with the help of advanced computer software. This process is like a "real combat exercise" for the special-shaped parts in the virtual world. Through simulation, engineers can clearly and intuitively understand the stress distribution of the special-shaped parts under various complex stress conditions. Through CAE simulation, it can be accurately seen which parts of a special-shaped part of the car chassis will be subjected to greater shear stress and which parts will be affected by tensile stress when braking suddenly. Based on these simulation results, engineers can determine the fiber direction and number of plies required for each part. For parts that are subjected to large tensile stress, just like building a bridge that needs to withstand huge tensile forces, it may be necessary to lay the fiber direction of the carbon fiber prepreg along the direction of the tensile force, and appropriately increase the thickness of the layer to improve the tensile strength of the part. In this way, the most suitable prepreg layering scheme is tailored for each special-shaped part to ensure that the product meets strict strength and performance requirements while reducing weight as much as possible, improving material utilization and reducing production costs.

Layering operation

Once the carefully designed layering scheme is determined, it enters the actual layering operation stage. This stage requires extremely high accuracy and quality control, just like performing a delicate operation in the microscopic world. Workers need to carefully lay the carbon fiber prepreg layer by layer on the mold in strict accordance with the design requirements. During the laying process, the direction of each layer of prepreg must be accurate, the deviation cannot exceed the slightest, and the fit between the layers must be tight and there must be no bubbles or gaps. Even a tiny bubble may be like a "time bomb" in the building, causing serious quality problems in the subsequent use of the special-shaped part. During the operation, experienced workers will skillfully use special tools such as rollers to carefully compact each layer of prepreg, just like a masseur carefully massaging each muscle, to completely remove the air between the layers so that the prepregs can be fully bonded to form a tight whole. In addition, the company has also introduced advanced optical detection equipment, which is like a keen "eye" to monitor the laying direction and quality of the prepreg in real time during the laying process. Once any problem is found, such as the direction of a layer of prepreg is deviated, or tiny bubbles appear between the layers, the detection system can immediately sound an alarm, and the workers can make adjustments in time to ensure that the laying quality is always at a high standard.

Layer sequence

The laying sequence also plays a vital role in the entire prepreg laying process. It is like the order of notes in a beautiful piece of music. Different arrangements will produce completely different effects. Prepregs with different properties may need to be laid in a specific order to achieve the best performance combination. For example, when manufacturing some special-shaped parts with complex curved shapes, it may be necessary to lay a layer of prepreg with higher flexibility first. This layer of prepreg is like a soft "cushion", which can better adapt to the complex curved surface shape of the special-shaped parts and lay a good foundation for the subsequent laying work. Then, a higher strength prepreg is laid on it to meet the strength requirements of the special-shaped parts in this part. Every product developed by the company has been carefully designed and rigorously tested. From the initial design to the final product molding, every link has been repeatedly scrutinized. In this way, it is ensured that the ply sequence can maximize the performance advantages of carbon fiber prepreg and meet the stringent requirements of the automotive industry for high performance of special-shaped parts.

Curing and molding

After the ply is completed, the curing and molding stage will follow. This stage is the key step to transform the laid carbon fiber prepreg into a carbon fiber special-shaped part with a specific shape and performance, just like turning a piece of soft clay into a hard ceramic through high-temperature firing. At this stage, multiple key parameters such as temperature, pressure and time need to be precisely controlled. A slight deviation in any parameter may have a significant impact on product quality. Take the autoclave molding process as an example. This is a process widely used in the molding of carbon fiber composite materials. First, carefully place the mold with prepreg in the autoclave, and then operate it in a vacuum state according to the pre-set specific heating, insulation and cooling curves by precisely controlling the temperature and pressure in the autoclave. During the heating process, the temperature should rise slowly so that the resin in the prepreg can soften and flow evenly and fully infiltrate the carbon fiber filaments; during the insulation stage, the temperature and pressure should be kept stable to allow sufficient chemical reaction between the resin and the carbon fiber to form a strong bond; during the cooling stage, the cooling speed should also be controlled to avoid defects such as cracks in the product due to rapid temperature changes. Through this precise control, the prepreg is cured and formed under a uniform temperature and pressure environment, and finally a carbon fiber special-shaped part with high surface quality and dense internal structure is produced, which meets the almost stringent requirements of the automotive industry for product quality.

III. Quality inspection throughout the whole process

(I) Internal defect detection

In order to ensure the integrity of the internal structure of the product, Dongli New Materials uses ultrasonic detection technology to detect defects inside the product. Ultrasonic waves are like a pair of "perspective eyes" that can penetrate objects. When ultrasonic waves propagate inside carbon fiber special-shaped parts, if they encounter defects such as bubbles and delamination, the propagation path and energy of ultrasonic waves will change. By detecting these changes, it is possible to accurately find out whether there are defects inside the product and the location and size of the defects. This detection technology can conduct a comprehensive inspection of the inside of the product without destroying the product, providing a strong guarantee for product quality.

(II) Mechanical properties test

In addition to internal defect detection, testing of mechanical properties such as strength and stiffness of special-shaped parts is also an important part of quality inspection. Dongli New Materials is equipped with advanced mechanical properties testing equipment, which can simulate various stress conditions that special-shaped parts may encounter during actual use, and perform mechanical properties tests such as stretching, bending, and compression on special-shaped parts. The data obtained through the test is compared with the design requirements to ensure that the mechanical properties of the product meet the design standards. Only products that have been strictly tested and meet the performance indicators will be allowed to enter the next production link or be finally delivered to customers.

English

English

中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt