Highly flexible carbon fiber unidirectional UD reinforcement cloth is a high-performance composite m...

In the precision-driven field of aerospace manufacturing, the performance of composite structures is...

Welcome to visit the website of Jiangyin Dongli New Materials Technology Co., Ltd.

English

English

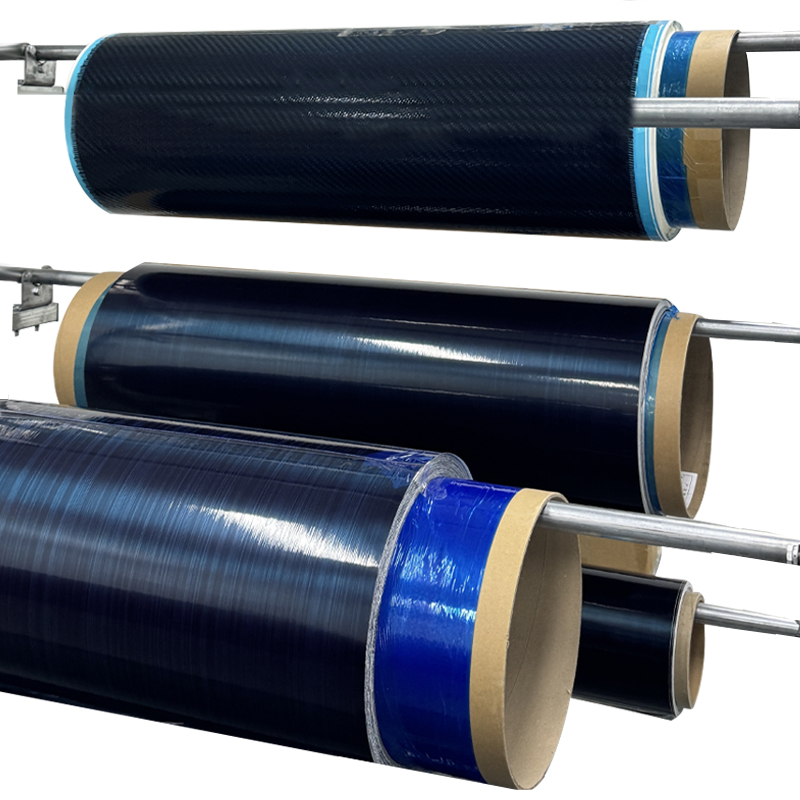

Highly Flexible Carbon Fiber Unidirectional UD Reinforcement Fabric

Highly Flexible Carbon Fiber Unidirectional UD Reinforcement Fabric

Highly flexible carbon fiber unidirectional UD reinforcement cloth is a high-performance composite m...

1k/3k/12k Carbon Fiber Plain Weave Fabric

1k/3k/12k Carbon Fiber Plain Weave Fabric

1K, 3K, 12K carbon fiber plain weave fabrics are high-performance textile materials made from carbon...

Abrasion-Resistant And High-Temperature-Resistant Carbon Fiber Twill Weave Fabric

Abrasion-Resistant And High-Temperature-Resistant Carbon Fiber Twill Weave Fabric

Wear-resistant and heat-resistant carbon fiber twill weave fabric is made of carbon fiber yarns wove...

Corrosion-Resistant And Drug-Resistant Satin Carbon Fiber Weave Fabric

Corrosion-Resistant And Drug-Resistant Satin Carbon Fiber Weave Fabric

Corrosion-resistant and drug-resistant satin carbon fiber woven fabric adopts satin weaving technolo...

Other Textured Carbon Fiber Woven Fabric

Other Textured Carbon Fiber Woven Fabric

Textured Carbon Fiber Woven Fabric is a high-performance composite material made of carbon fiber tow...

Red/Black Aramid Carbon Mixed Carbon Fiber Woven Fabric

Red/Black Aramid Carbon Mixed Carbon Fiber Woven Fabric

Red/black aramid carbon fiber woven fabric is made of aramid fiber and carbon fiber interwoven in a ...

3k 1000d/1500d Plain/Twill Aramid Carbon Mixed Carbon Fiber Woven Fabric

3k 1000d/1500d Plain/Twill Aramid Carbon Mixed Carbon Fiber Woven Fabric

3K 1000D/1500D plain/twill aramid mixed carbon fiber woven fabric is made of aramid fiber and carbon...

Yellow/black I-beam Aramid Carbon Blend

Yellow/black I-beam Aramid Carbon Blend

Yellow/black I texturedaramid carbon fiber woven fabric is interlaced with yellow aramid fiber and b...

Advanced weaving and molding capabilities tailored to your needs.

Full-spectrum capabilities from prepregging to assembly.

Certified under ISO 9001:2015, ensuring precision and reliability.

Serving clients across aerospace, automotive, and industrial markets worldwide.

At Jiangyin Dongli New Materials Technology Co., Ltd., we have built a robust manufacturing base covering 32,000㎡ to serve the evolving demands of industries worldwide. Our facilities are equipped with advanced technology and tailored workflows, ensuring the higher standards in composite material production.

![]() Precision environment: Constant temperature workshop and 1.100,000-grade purification area to ensure material integrity and production accuracy.

Precision environment: Constant temperature workshop and 1.100,000-grade purification area to ensure material integrity and production accuracy.

![]() Full range of capabilities: From fiber weaving to prepreg production to integrated production of advanced forming technologies such as RTM, 2.vacuum infusion and hot pressing.

Full range of capabilities: From fiber weaving to prepreg production to integrated production of advanced forming technologies such as RTM, 2.vacuum infusion and hot pressing.

![]() Sustainable processes: Efficient use of resources and innovative design ensure environmentally friendly production.

Sustainable processes: Efficient use of resources and innovative design ensure environmentally friendly production.

![]() High capacity: The loom has a daily output of 4,000㎡, supported by an autonomous tension control and feeding system.

High capacity: The loom has a daily output of 4,000㎡, supported by an autonomous tension control and feeding system.

Our facilities not only represent efficient manufacturing but also demonstrate our commitment to advancing composite technology. By continuously investing in our infrastructure, we aim to redefine both performance and sustainability in the industry.

From carbon fiber drones to automotive trim panels, discover how our expertise transforms ideas into high-performance solutions.

Fiber composites are used in the manufacture of fuselages and airfoils for UAVs to reduce weight and improve flight efficiency.

They are used to produce lightweight components for automobiles, such as body panels, chassis and hoods, to improve fuel efficiency and performance.

Used in the manufacture of bodies and internal structures for light rail vehicles and high-speed trains to reduce overall weight and energy consumptio...

Used in the manufacture of high-performance tennis rackets, bicycle frames, skis, etc. to provide better flexibility and durability.

Used in the manufacture of lightweight and durable medical equipment cases that are easy for healthcare professionals to carry and transport.

In the precision-driven field of aerospace manufacturing, the performance of composite structures is...

In the evolving landscape of advanced composites, carbon aramid fabric stands as a sophisticated hyb...

In the evolving landscape of structural engineering and high-performance manufacturing, the choice o...

Carbon aramid fabric combines high-strength aramid fibers with carbon reinforcement, providing excep...

1. Understanding Material Challenges High-strength fiber machining parameters must be carefully sele...

I. The Complexities of Hybrid Composites The carbon aramid fabric hybrid composite is a material eng...