1. The core advantages and technical characteristics of High-Performance Composites

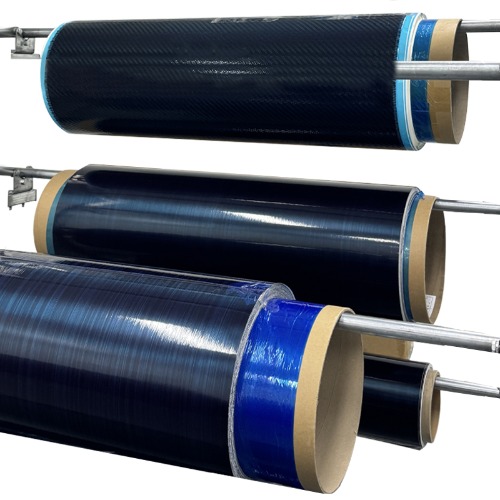

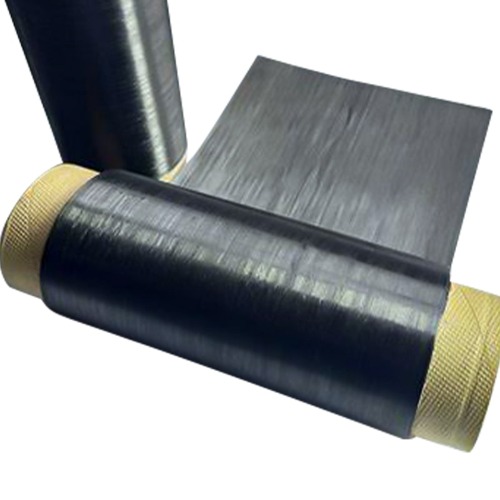

High-performance composite materials are composed of two or more materials of different properties, combining their respective advantages to form a new material system with excellent performance. Compared with traditional metal materials, High-Performance Composites show the following core advantages:

Lightweight and high strength: The density of composite materials is much lower than that of metal materials, and its tensile strength, bending strength and impact toughness are significantly improved, effectively reducing the overall weight of the aircraft and improving fuel efficiency.

Excellent corrosion resistance: High-performance composite materials have extremely strong resistance to chemicals, salt spray and other environments, extending the service life of aircraft structural parts and reducing maintenance costs.

Good design flexibility: By changing the fiber type, arrangement and matrix materials, designers can customize composite materials with different properties according to their needs to meet the diverse requirements of complex flight environments.

Excellent fatigue resistance and high temperature resistance: The aircraft will withstand severe temperature changes and periodic loads during high-altitude and high-speed flight. High-Performance Composites can maintain stable performance and ensure safety and reliability.

2. Breakthrough application cases in the field of aerospace

In recent years, with the rapid development of composite material technology, High-Performance Composites has become increasingly widely used in the aerospace field and has become an important material for design and manufacturing.

Lightweight structural parts

Key structural components such as aircraft fuselage, wings, and tails are made of high-performance composite materials, which not only effectively reduces the aircraft's own weight, but also improves structural strength and rigidity. For example, the use of composite wings greatly reduces the weight of the wing, resulting in reduced fuel consumption of the aircraft and enhanced battery life.

High temperature application of engine components

The internal environment of the aircraft engine is extremely complex and needs to withstand high temperatures and high pressures. High-performance composite materials such as carbon fiber reinforced ceramic matrix composites (CMC) are gradually replacing traditional metal materials for engine turbine blades and heat shields, improving engine efficiency and life due to their excellent high temperature and wear resistance.

Satellite and spacecraft manufacturing

Satellites and deep space detectors have extremely high requirements for the lightweight and radiation resistance of materials. High-Performance Composites not only meet these needs, but also have excellent electromagnetic shielding performance to ensure the normal operation of the electronic equipment inside the spacecraft.

Drones and high-speed aircraft

UAVs and high-speed aircraft have extremely high requirements for maneuverability and endurance. High-performance composites provide key support for efficient flight and long-term battery life of drones by reducing body weight and increasing structural strength.

3. Industry challenges and future development directions

Although the application of High-Performance Composites in the aerospace field has brought many advantages, related technologies still face many challenges:

Cost control

The manufacturing cost of high-performance composite materials is higher than that of traditional metal materials, especially high-end carbon fiber composite materials, which limits its application in some mid- and low-end aerospace products. In the future, through process innovation and large-scale production, costs are expected to be further reduced.

Manufacturing process complexity

Composite material manufacturing involves multiple processes and strict quality control, and any minor defects may affect material performance. The development of intelligent and automated production equipment and testing technologies is the key to improving product consistency and performance.

Recycling and environmental protection issues

The recycling of high-performance composite materials is still in its infancy, and environmental protection issues are increasingly paying attention to the industry. Developing recyclable green composite materials and efficient recycling processes will become an important direction in the future.

English

English  中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt