- 1 Technical principles of Carbon Fiber Sheets/Plates surface treatment

- 2 Key technical breakthroughs in improving wear resistance

- 3 Innovative solutions for aesthetic optimization

- 4 Application Prospects of Carbon Fiber Sheets/Plates Surface Treatment

- 5 The future development direction of surface treatment technology

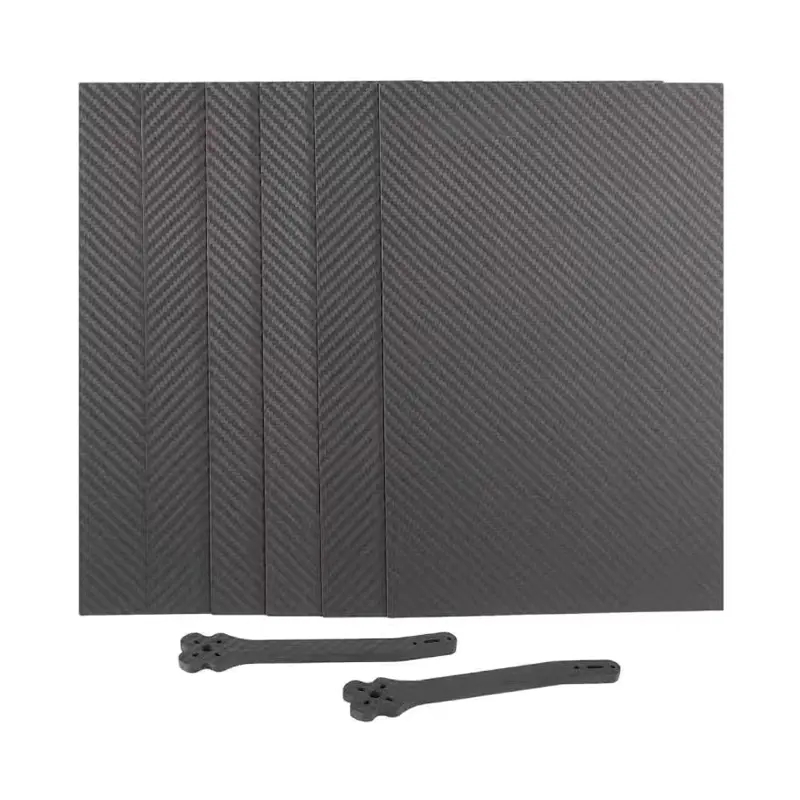

In the field of high-end manufacturing, Carbon Fiber Sheets/Plates (carbon fiber sheets) have become a key material in the aerospace, automobile manufacturing, consumer electronics and other industries with its excellent strength-to-weight ratio and excellent mechanical properties. However, the surface wear and appearance aging problems faced by traditional carbon fiber sheets during long-term use have always been technical bottlenecks that restrict their wider application. Recently, the field of materials science has made breakthrough progress in Carbon Fiber Sheets/Plates surface treatment technology, and has achieved dual improvements in wear resistance and aesthetics through innovative processes, opening up a broader space for the application of carbon fiber sheets.

Technical principles of Carbon Fiber Sheets/Plates surface treatment

The new surface treatment technology mainly improves the surface characteristics of Carbon Fiber Sheets/Plates from the molecular level. Through advanced processes such as plasma treatment and nanocoating deposition, a multi-layer protective structure is built on the surface of the material. These treatments not only enhance surface hardness, but also form a dense protective layer, effectively blocking the erosion of the substrate by the external environment. It is particularly worth mentioning that some innovative processes can enhance wear resistance while giving Carbon Fiber Sheets/Plates a richer surface texture and visual effect, meeting the high requirements for product appearance in different application scenarios.

In terms of process control, modern surface treatment technology achieves precise control of treatment thickness and uniformity. With a computer-aided automated control system, it is possible to ensure that every Carbon Fiber Sheets/Plates achieves a consistent surface treatment effect. This precision control not only improves the stability of product quality, but also provides technical guarantees for customized needs in special application scenarios.

Key technical breakthroughs in improving wear resistance

The improvement of Carbon Fiber Sheets/Plates' wear resistance mainly depends on three major technological breakthroughs. First of all, the development and application of superhard coatings, using advanced coating materials such as diamond-like carbon (DLC), which significantly improves the surface hardness and greatly reduces the friction coefficient. The second is the innovation of interface combination technology. Through special surface activation treatment, the bonding strength between the coating and the substrate is enhanced, and the coating peeling problem common in traditional processes is avoided. The third is the introduction of self-repair technology. Some new treatment processes can automatically repair microscopic defects after slight wear, thereby extending the service life.

These technological advancements have made a qualitative leap in durability of processed Carbon Fiber Sheets/Plates in harsh environments. Experimental data show that the wear resistance performance of the optimized plate can be improved by more than 300%, which is especially suitable for high friction and high load industrial scenarios. At the same time, excellent wear resistance also means that the product can maintain its initial appearance for a long time, greatly enhancing its commercial value.

Innovative solutions for aesthetic optimization

While improving functionality, the new representative surface processing technology also brings unprecedented aesthetic expression to Carbon Fiber Sheets/Plates. By precisely controlling the surface texture and gloss, the treated sheet can present different visual effects from matte to highlight. Advanced coloring technology breaks through the limitation of single color of traditional carbon fiber products, and achieves rich color selection while maintaining material characteristics.

It is particularly worth noting that some innovative processes can create a unique three-dimensional texture effect, making the surface of Carbon Fiber Sheets/Plates present a delicate three-dimensional texture. This treatment not only enhances the visual appeal of the product, but also further enhances functionality through specific surface structural designs. For example, some microtexture designs can improve the anti-fingerprint properties of materials or enhance the anti-slip properties of the surface, achieving a perfect combination of aesthetics and practicality.

Application Prospects of Carbon Fiber Sheets/Plates Surface Treatment

The optimized Carbon Fiber Sheets/Plates has broad application prospects in all fields. In the field of transportation, carbon fiber boards with high wear resistance and aesthetics are very suitable for use in automotive interior and exterior parts, which can not only meet the strict usage environment requirements, but also enhance the texture of the vehicle. In the consumer electronics industry, surface-treated Carbon Fiber Sheets/Plates provides a lightweight and stylish appearance solution for high-end electronics.

The industrial equipment field also benefits from this technological advancement. The high-performance Carbon Fiber Sheets/Plates used in chemical machinery, precision instruments and other equipment not only extends the service life through surface treatment, but also improves the overall appearance of the equipment. New possibilities have also emerged in the field of architectural decoration. Specially treated carbon fiber boards can be used as high-end decorative materials to meet the pursuit of lightweight, high-strength and beautiful building materials in modern buildings.

The future development direction of surface treatment technology

The future development of Carbon Fiber Sheets/Plates surface treatment technology will show three major trends. The first is the research and development of intelligent processing processes. By introducing artificial intelligence and Internet of Things technology, real-time monitoring and automatic optimization of processing processes can be achieved, further improving the consistency and reliability of processing effects. The second is the innovation of environmentally friendly treatment methods, the development of low-energy-consuming and pollution-free green treatment processes to reduce the environmental burden in the production process. The third is the development of multi-functional integrated. The future surface treatment will not only be limited to improving wear resistance and aesthetics, but will also integrate anti-static, thermal conductivity, electromagnetic shielding and other functions to meet more complex application needs.

The adaptive surface technology that materials scientists are exploring is particularly striking. This innovative technology enables the surface characteristics of Carbon Fiber Sheets/Plates to be automatically adjusted according to environmental changes, such as enhancing hydrophobicity in humid environments and automatically increasing lubricity under high friction conditions. The implementation of this type of intelligent surface will completely change the application model of carbon fiber sheets and create a new era of materials science.

English

English  中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt