In the rapidly evolving landscape of advanced materials, Epoxy Carbon Fiber Prepreg has emerged as a game - changing solution, powering innovation across multiple industries with its exceptional properties and versatile applications.

Unparalleled Material Characteristics

Optimal Fiber - Resin Synergy

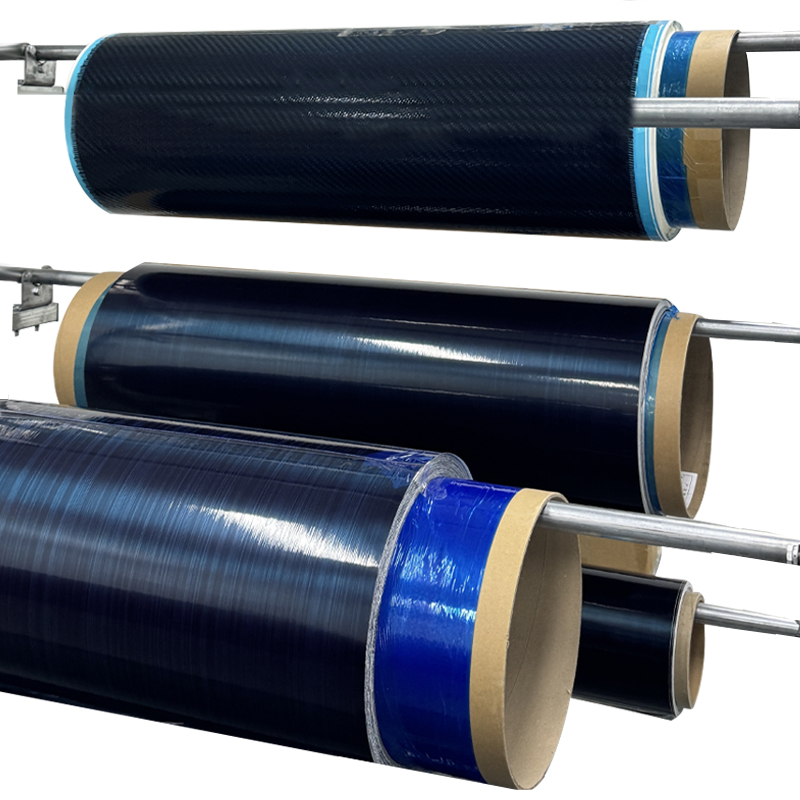

Epoxy Carbon Fiber Prepreg is a composite material that combines the strength of carbon fibers with the excellent adhesive and mechanical properties of epoxy resin. The precise impregnation process ensures an ideal balance between the carbon fibers and the epoxy matrix. This synergy results in a material with an incredibly high strength - to - weight ratio. Carbon fibers, known for their tensile strength, are uniformly distributed within the epoxy resin, enabling the prepreg to withstand significant loads while remaining lightweight. This makes it a preferred choice for applications where weight reduction is crucial without sacrificing structural integrity.

Superior Mechanical and Chemical Resistance

The epoxy resin in the prepreg imparts outstanding mechanical properties. It provides excellent impact resistance, protecting components from damage caused by sudden forces. Additionally, Epoxy Carbon Fiber Prepreg exhibits remarkable chemical resistance, making it suitable for use in harsh environments. Whether it's exposure to corrosive chemicals, extreme temperatures, or moisture, this material maintains its performance, ensuring the longevity and reliability of products in industries such as aerospace, automotive, and marine.

Manufacturing Precision and Process Excellence

Advanced Impregnation Techniques

The production of Epoxy Carbon Fiber Prepreg involves sophisticated impregnation techniques. Manufacturers use state - of - the - art equipment to ensure that the carbon fibers are evenly coated with the epoxy resin. This precise control over the impregnation process is essential for achieving consistent quality and performance. By adjusting parameters such as resin viscosity, temperature, and pressure, producers can optimize the properties of the prepreg, tailoring it to meet the specific requirements of different applications.

Customization for Varied Applications

Epoxy Carbon Fiber Prepreg can be customized in terms of fiber orientation, resin content, and thickness. Different fiber orientations, such as unidirectional or bidirectional, can be selected depending on the load - bearing requirements of the final product. Adjusting the resin content allows for fine - tuning of the material's mechanical properties, while varying the thickness enables the creation of components with different levels of strength and flexibility. This high degree of customization makes Epoxy Carbon Fiber Prepreg adaptable to a wide range of industries and applications.

Diverse Industry Applications

Aerospace Advancements

In the aerospace industry, Epoxy Carbon Fiber Prepreg has become indispensable. It is used to manufacture critical components such as aircraft wings, fuselages, and engine parts. The lightweight yet strong nature of the prepreg helps reduce the overall weight of the aircraft, leading to improved fuel efficiency and increased range. Moreover, its excellent mechanical properties ensure the safety and reliability of these components during flight.

Automotive Innovation

Automotive manufacturers are also increasingly turning to Epoxy Carbon Fiber Prepreg to enhance vehicle performance. It is used in the production of high - performance parts such as body panels, drive shafts, and suspension components. By using this material, cars can achieve better handling, acceleration, and fuel economy, while also reducing emissions.

Market Growth and Future Prospects

Expanding Market Demand

The demand for Epoxy Carbon Fiber Prepreg is on the rise, driven by the growing need for high - performance materials in various industries. As companies strive to develop lighter, stronger, and more durable products, the market for this prepreg is expected to continue its upward trajectory.

Technological Advancements Ahead

Looking to the future, continuous research and development will likely lead to further improvements in Epoxy Carbon Fiber Prepreg. Advancements in manufacturing processes, new resin formulations, and enhanced fiber - resin interfaces are on the horizon. These developments will open up new possibilities for applications in emerging industries and contribute to the continued growth of this innovative material.

English

English  中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt