- 1 I. The Complexities of Hybrid Composites

- 2 II. The Resin Wetting Challenge: Aramid's Low Surface Energy

- 3 III. Solutions: Surface Modification and Resin Optimization

- 4 IV. Consequences: Void Content and Mechanical Degradation

- 5 V. Quality Control and Full Process Expertise

- 6 VI. Engineering the Interface

- 7 VII. Frequently Asked Questions (FAQs)

- 7.1 Q1: Why is aramid fiber naturally resistant to resin wetting?

- 7.2 Q2: What is the single most common defect caused by poor resin wetting in carbon aramid fabric?

- 7.3 Q3: Which is more effective for solving the low surface energy problem: fiber surface treatment or resin viscosity reduction?

- 7.4 Q4: How does poor wetting affect the impact resistance, which is a key benefit of aramid fiber?

- 7.5 Q5: Why do manufacturers need specialized environments (like 100,000-grade purification zones) for processing carbon aramid fabric?

I. The Complexities of Hybrid Composites

The carbon aramid fabric hybrid composite is a material engineered for extreme environments, offering the high stiffness and strength of carbon fibers combined with the exceptional impact resistance and damage tolerance of aramid fibers. This blend is critical in technical sectors such as aerospace engineering, automotive manufacturing, and high-performance sports equipment. However, manufacturing these hybrid components presents a significant technical hurdle: the inherent low surface energy of aramid fibers, which often results in poor resin wetting and subsequently leads to high void content and compromised mechanical properties. Jiangyin Dongli New Materials Technology Co., Ltd. specializes in the comprehensive development and manufacturing of these high-performance fiber composite materials. Operating from a 32,000-square-meter industrial complex, including precision-controlled production environments like climate-regulated workshops and 100,000-grade purification zones, we leverage integrated material innovation and engineering expertise. As a one-stop factory, our capabilities span the entire process, from weaving and prepreg production to final composite manufacturing using technologies like Autoclave, RTM, and PCM.

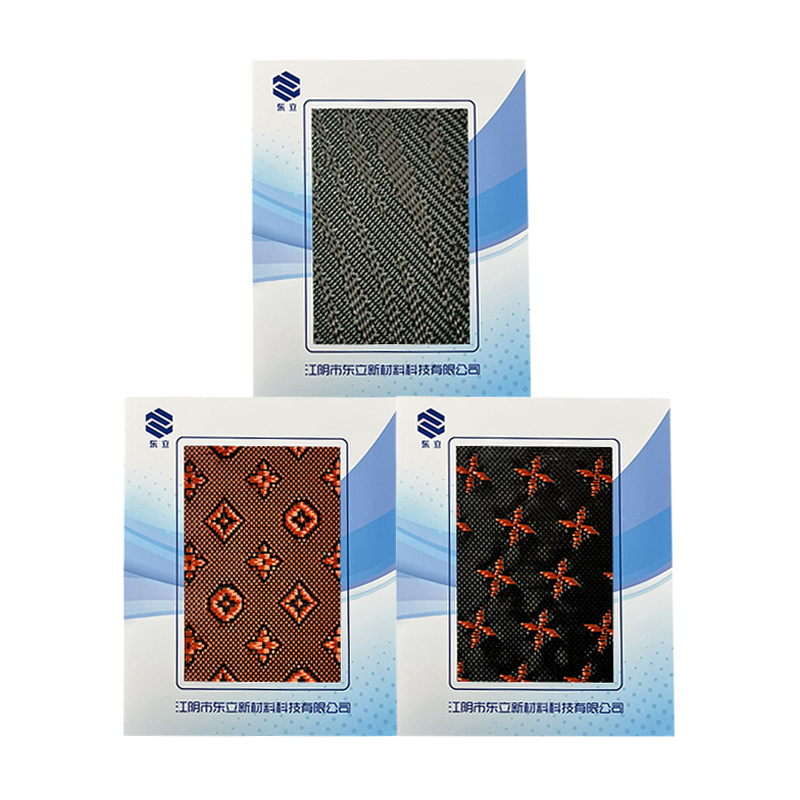

3k 1000d/1500d Plain/Twill Aramid Carbon Mixed Carbon Fiber Woven Fabric

II. The Resin Wetting Challenge: Aramid's Low Surface Energy

Wetting is governed by the principles of surface chemistry, specifically the balance between the fiber's surface energy and the resin's surface tension. Aramid fibers, due to their highly oriented aromatic polymer structure, are chemically inert and have a very low surface energy (often around 30-40 mN/m). This low surface energy results in a large contact angle with standard epoxy or vinyl ester resins, preventing the resin from capillary action (spreading) and thoroughly penetrating the fiber bundles. This lack of interfacial adhesion drastically compromises the structural load transfer, which is the foundational purpose of any composite.

A. Aramid Fiber Low Surface Energy Prepreg Solution

For the prepreg process, where the resin is partially cured onto the fiber, the aramid fiber low surface energy prepreg solution often involves manipulating processing conditions to enhance penetration. This typically includes increasing the prepreg temperature to lower the resin's viscosity temporarily and applying higher pressure during the initial impregnation phase. While the prepreg process (used extensively by Dongli) generally yields lower void content than wet layup due to controlled resin content and vacuum consolidation, the aramid component still presents challenges compared to the easily wetted carbon fibers within the carbon aramid fabric. The comparison of processing methods underscores the difficulty:

| Process Method | Primary Method of Wetting | Typical Void Content Achieved | Wetting Challenge Mitigation |

|---|---|---|---|

| Prepreg (Autoclave/Oven Cure) | Heat and Pressure/Vacuum | < 2% (Aerospace Target) | Optimized resin viscosity, high pressure |

| Wet Layup (Hand or Infusion) | Capillary Action/Vacuum | > 3% - 5% (Higher Risk) | Lower resin surface tension, longer infusion time |

III. Solutions: Surface Modification and Resin Optimization

Engineers must actively intervene to improve the carbon aramid fabric interface, employing either fiber surface modification or resin formulation adjustments.

A. Surface Treatment for Aramid Fiber Resin Adhesion

The most impactful intervention is pre-treating the aramid filaments. Effective surface treatment for aramid fiber resin adhesion includes chemical etching (e.g., acid or alkaline solutions) or plasma treatment. These processes introduce active functional groups (elike hydroxyl or carboxyl groups) onto the aramid surface, increasing its surface energy and creating strong covalent bonds or hydrogen bonds with the polymer matrix. The critical trade-off is ensuring the treatment improves adhesion without causing structural damage to the aramid's highly crystalline structure, which would compromise its inherent tensile strength.

B. Carbon Aramid Fabric Resin Wetting Improvement Methods

If fiber modification is not feasible, resin modification must be employed. Carbon aramid fabric resin wetting improvement methods focus on adjusting the resin's surface tension to be lower than the fiber's surface energy (Young's Equation). This involves adding specific surfactants or non-reactive diluents to the resin formulation. Additionally, processes like Resin Transfer Molding (RTM) or Vacuum-Assisted Resin Infusion (VARI), utilized in Dongli's facility, rely on precise vacuum pressure and controlled flow rates to mechanically force the resin into the tightly woven aramid bundles, compensating for the poor natural wetting.

IV. Consequences: Void Content and Mechanical Degradation

Failure to achieve sufficient resin wetting has direct, quantifiable negative impacts on the structural integrity and performance of the finished carbon aramid fabric composite part.

A. Hybrid Carbon Aramid Composite Void Content Impact

Resin wetting deficiency is the leading cause of porosity, or void content (air bubbles trapped within the laminate). Voids act as stress concentrators and fracture initiation sites. The hybrid carbon aramid composite void content impact is most severe on matrix-dominated properties, particularly Inter-Laminar Shear Strength (ILSS). High void content drastically reduces the material's ability to resist delamination. The degradation of mechanical properties due to voids is well-documented:

| Void Content (%) | Impact on Inter-Laminar Shear Strength (ILSS) | Impact on Flexural Strength |

|---|---|---|

| < 1% (Aerospace Grade) | Minimal Degradation (< 5%) | Minimal Degradation |

| 3% - 5% (Standard Industrial) | Significant Degradation (15% - 25%) | Noticeable Degradation (10% - 20%) |

| > 5% (Unacceptable) | Severe Degradation (> 30%) | High Risk of Failure |

B. Wet Layup Carbon Aramid Fabric Mechanical Properties

For composite structures fabricated using the wet layup carbon aramid fabric mechanical properties method, poor wetting also specifically compromises the key performance characteristics provided by the aramid fiber. Aramid is included primarily for its high-energy absorption capacity (impact resistance). If the resin does not fully adhere to the aramid fiber, the load cannot be effectively transferred, reducing the fiber's ability to halt crack propagation, thus compromising impact resistance and drastically lowering the fatigue life of the entire laminate.

V. Quality Control and Full Process Expertise

At Jiangyin Dongli New Materials Technology Co., Ltd., we mitigate these wetting and void issues through a fully integrated, one-stop approach. Our controlled production environment, including 100,000-grade purification zones, minimizes contamination that can disrupt wetting. We utilize advanced manufacturing processes, including Autoclave, RTM, RMCP, PCM, WCM, and spraying technologies, ensuring every stage, from R&D of high-performance fiber fabrics to the final composite product, adheres to rigorous quality standards, minimizing the void content and guaranteeing the specified mechanical performance.

VI. Engineering the Interface

Maximizing the structural and mechanical performance of a carbon aramid fabric composite hinges on successfully engineering the fiber-resin interface to overcome aramid's low surface energy. Whether through sophisticated aramid fiber low surface energy prepreg solution methods or pre-treatment of the fiber using surface treatment for aramid fiber resin adhesion techniques, meticulous process control and material science application are essential. B2B buyers seeking high-reliability components must partner with manufacturers possessing the expertise and full-process control, like Dongli, to ensure that low void content translates directly into high mechanical strength and exceptional durability.

VII. Frequently Asked Questions (FAQs)

Q1: Why is aramid fiber naturally resistant to resin wetting?

- A: Aramid fiber is composed of highly oriented aromatic polymer chains that are chemically inert and lack active functional groups on the surface. This results in an inherently low surface energy, which causes high surface tension resins to bead up (high contact angle) rather than spread and penetrate effectively.

Q2: What is the single most common defect caused by poor resin wetting in carbon aramid fabric?

- A: The single most common defect is high void content (porosity). Unwetted fiber bundles trap air bubbles during the curing process, and these voids act as critical stress concentrators, particularly weakening the inter-laminar shear strength (ILSS) of the hybrid carbon aramid composite void content impact.

Q3: Which is more effective for solving the low surface energy problem: fiber surface treatment or resin viscosity reduction?

- A: Fiber surface treatment (e.g., plasma or chemical) is generally more fundamentally effective because it chemically alters the fiber's surface energy, promoting actual chemical bonding. Resin viscosity reduction, one of the carbon aramid fabric resin wetting improvement methods, helps mechanically but does not improve the chemical adhesion strength at the interface.

Q4: How does poor wetting affect the impact resistance, which is a key benefit of aramid fiber?

- A: Poor wetting isolates the aramid fibers from the load-bearing resin matrix. During an impact, the energy cannot be effectively transferred from the matrix to the high-toughness aramid fibers, preventing the fibers from absorbing the energy and halting crack propagation, thus compromising the composite's overall impact performance.

Q5: Why do manufacturers need specialized environments (like 100,000-grade purification zones) for processing carbon aramid fabric?

- A: Precision environments are crucial because surface contaminants (like dust, oil, or moisture) can drastically reduce the fiber's already low surface energy, leading to even worse resin wetting. Clean rooms ensure the material is processed under optimal, contamination-free conditions to maximize the potential of the chosen aramid fiber low surface energy prepreg solution.

English

English  中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt