- 1 Defining the Material: What is Pure Carbon Woven Fabric?

- 2 The Paramount Advantage: Unmatched Weight Reduction

- 3 Exceptional Strength and Rigidity: The Backbone of Safety and Dynamics

- 4 Long-Term Value: Examining the Durability of Woven Carbon Fiber Composites

- 5 Manufacturing and Design Freedom: Exploring How is Carbon Fabric Used in Automotive Manufacturing

- 6 A Balanced View: Cost vs Performance of Carbon Fiber in Cars

- 7 FAQ

- 7.1 Is carbon fiber stronger than steel?

- 7.2 Why is carbon fiber so expensive in automotive applications?

- 7.3 Can carbon fiber car parts be repaired?

- 7.4 What are the main disadvantages of using carbon fiber in mass-produced cars?

- 7.5 How does the choice of weave pattern affect the final part's properties?

The relentless pursuit of efficiency, performance, and safety in the automotive industry has catalyzed a materials revolution, shifting the focus from traditional metals to advanced composites. At the forefront of this shift is Pure Carbon Woven Fabric. This engineered material, once confined to the realms of aerospace and elite motorsport, is now increasingly critical in high-performance road cars and future mobility solutions. This analysis delves deep into the multifaceted advantages of pure carbon woven fabric, examining how its unique properties are reshaping automotive design and manufacturing.

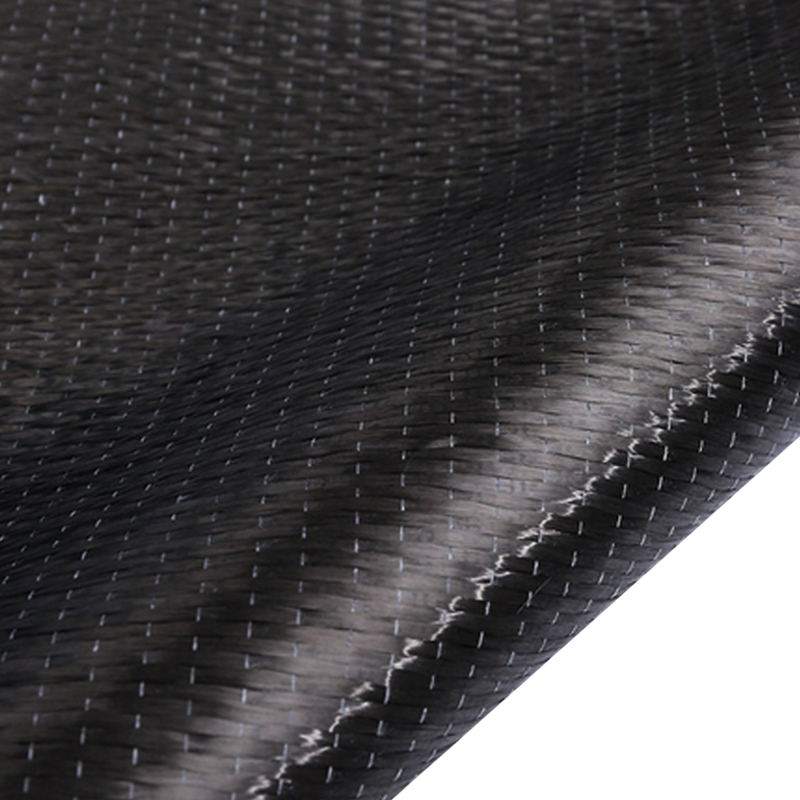

Highly Flexible Carbon Fiber Unidirectional UD Reinforcement Fabric

Defining the Material: What is Pure Carbon Woven Fabric?

Before assessing its advantages, it's essential to understand what this material is. Pure Carbon Woven Fabric is a textile made by interlacing strands of carbon fiber, each one composed of thin, tightly bound carbon atoms. These fabrics are not used alone; they are impregnated with a polymer resin (like epoxy) to form a Carbon Fiber Reinforced Polymer (CFRP) composite. The woven fabric provides the strength and stiffness, while the resin matrix binds the fibers together, transfers loads, and determines the composite's environmental resistance.

The Anatomy of a Carbon Fiber Weave

The fundamental unit of carbon fabric is the filament, which is bundled into a tow. These tows are then woven on industrial looms into flat sheets. The specific way these tows are interlaced defines the fabric's handling characteristics, drape, and mechanical properties.

- Filaments: Extremely thin strands of carbon, typically thousands bundled together to form a tow.

- Tow Size: Denoted by a number like 3K or 12K, indicating the number of filaments (e.g., 3,000 or 12,000) in a single tow.

- Weave Pattern: The architectural pattern created by interlacing warp (longitudinal) and weft (transverse) tows.

Exploring Common Carbon Fiber Weave Types for Car Parts

The choice of weave is a critical design decision, balancing aesthetics, formability, and structural performance. Different carbon fiber weave types for car parts are selected based on the application's requirements.

- Plain Weave: The most basic and stable pattern, where each tow passes over and under one another. It offers good stability but lower drapeability for complex curves.

- Twill Weave (2x2, 4x4): Characterized by a diagonal rib pattern. Twill weaves, especially 2x2, offer an excellent balance of drapeability, stability, and is the most recognizable aesthetic in automotive applications.

- Satin Weave (4-Harness, 8-Harness): Tows pass over multiple others before going under one. This creates a fabric with excellent drapeability for complex contours and a high-strength potential, but it is less stable and can be more difficult to handle.

- Unidirectional (UD) Fabric: While not a weave, UD fabric consists of all tows running parallel. It is not a true "woven" fabric but is often used in conjunction with them to place maximum strength and stiffness in a single, primary load direction.

The Paramount Advantage: Unmatched Weight Reduction

The most significant and celebrated benefit of carbon fiber composites is their exceptional strength at a very low density. This directly translates to substantial weight savings, which is the holy grail in automotive engineering.

Quantifying the Benefits of Carbon Fiber in Vehicle Weight Reduction

Replacing traditional materials like steel or aluminum with CFRP can lead to weight reductions of 40% to 60% for the same component, while often increasing strength. This dramatic saving is a key enabler for modern vehicle design.

- Direct Mass Reduction: Lighter body panels, chassis components, and interior parts directly lower the vehicle's curb weight.

- Downsizing Cascade: A lighter vehicle requires a smaller, lighter engine for the same performance, which in turn needs a smaller fuel tank and a less robust suspension, creating a virtuous cycle of weight saving.

- Improved Power-to-Weight Ratio: For performance vehicles, this is the single most important metric for acceleration and agility.

The Ripple Effect on Performance and Efficiency

Weight reduction is not an end in itself; its value is realized through profound improvements in vehicle dynamics and efficiency.

- Enhanced Acceleration and Braking: A lighter car requires less energy to accelerate and less force to decelerate, improving both 0-60 mph times and braking distances.

- Superior Fuel Efficiency and EV Range: For internal combustion engines, less weight means better fuel economy. For electric vehicles (EVs), it is critical for extending driving range without increasing battery size and weight.

- Reduced Emissions: Lower fuel consumption directly correlates to lower CO2 emissions, helping manufacturers meet stringent environmental regulations.

Exceptional Strength and Rigidity: The Backbone of Safety and Dynamics

Beyond mere lightness, Pure Carbon Woven Fabric composites provide mechanical properties that surpass those of metals, contributing directly to vehicle safety and driving dynamics.

Superior Strength-to-Weight Ratio Compared to Metals

When assessed on an equal-weight basis, carbon fiber composites can be significantly stronger and stiffer than high-strength steel or aluminum alloys. This allows for the design of components that are both lighter and more robust.

- Tensile Strength: Carbon fiber exhibits extremely high resistance to being pulled apart, which is crucial for structural members under tension.

- Specific Stiffness: The stiffness (modulus of elasticity) per unit density of carbon fiber is exceptionally high, meaning it resists deformation under load very effectively for its weight.

Enhancing Torsional Rigidity for Superior Handling

Torsional rigidity refers to a chassis's resistance to twisting. A stiffer chassis provides a more stable platform for the suspension to work from, resulting in more precise handling, better cornering stability, and improved feedback to the driver. The high specific stiffness of carbon fiber composites makes them ideal for manufacturing monocoques and structural braces that dramatically increase a vehicle's torsional rigidity.

Long-Term Value: Examining the Durability of Woven Carbon Fiber Composites

The advantages of carbon fiber extend beyond initial performance to long-term reliability and resilience, a key aspect of the durability of woven carbon fiber composites.

Corrosion and Fatigue Resistance

Unlike metals, carbon fiber does not rust or corrode when exposed to moisture, salt, or chemicals. Furthermore, it exhibits excellent fatigue resistance, meaning it can withstand repeated cycles of stress and loading without cracking or failing, a critical property for components subjected to vibrations and road imperfections over the vehicle's lifetime.

- Corrosion Immunity: Eliminates the need for heavy and complex anti-corrosion coatings, contributing to long-term weight and maintenance savings.

- Superior Fatigue Life: CFRP components often have a much longer fatigue life than equivalent aluminum or steel parts, enhancing durability and safety.

Impact Absorption and Damage Tolerance

While often perceived as brittle, well-engineered carbon fiber composites are excellent at absorbing impact energy. In a crash, the composite structure can be designed to crush in a controlled manner, dissipating energy that would otherwise be transferred to the occupants. The woven nature of the fabric helps to contain damage, preventing it from propagating catastrophically across the entire structure.

Manufacturing and Design Freedom: Exploring How is Carbon Fabric Used in Automotive Manufacturing

The practical application of this material is as important as its intrinsic properties. Understanding how is carbon fabric used in automotive manufacturing reveals a key advantage: design freedom.

Versatile Forming Processes for Complex Shapes

The dry fabric is flexible and can be draped over complex, double-curved molds. This allows for the creation of large, single-piece components that would be impossible or prohibitively expensive to create from metal. Specialized manufacturers like Jiangyin Dongli New Materials Technology Co., Ltd. leverage a suite of processes to transform fabric into final parts.

- Prepreg Layup & Autoclave Curing: Using fabric pre-impregnated with resin (prepreg) and cured under high heat and pressure in an autoclave for the highest possible quality and performance.

- Resin Transfer Molding (RTM): Dry fabric is placed in a closed mold, and resin is injected under pressure, ideal for complex, high-volume production.

- Wet Layup: A more manual process where resin is applied to the dry fabric by hand in an open mold, suitable for prototyping and low-volume parts.

Enabling Innovative and Aerodynamic Designs

This formability allows designers to break free from the constraints of metal stamping. They can integrate functions, create more organic and aerodynamically efficient shapes, and reduce the number of parts and fasteners required, further saving weight and simplifying assembly.

A Balanced View: Cost vs Performance of Carbon Fiber in Cars

Any analysis would be incomplete without addressing the primary barrier to widespread adoption: cost. The decision to use carbon fiber is a constant evaluation of cost vs performance of carbon fiber in cars.

The following table provides a clear comparison of key factors influencing the cost-performance calculus.

| Factor | Traditional Metals (Steel/Aluminum) | Carbon Fiber Composites |

| Material Cost | Low | Very High |

| Manufacturing Cost | Low to Moderate (stamping, welding) | High (manual labor, energy-intensive curing) |

| Weight | High | Very Low |

| Strength-to-Weight Ratio | Moderate | Exceptional |

| Design Freedom | Limited | Extensive |

| Primary Application | Mass-market vehicles | High-performance, luxury, and critical lightweighted components |

FAQ

Is carbon fiber stronger than steel?

On a weight-for-weight basis, yes, carbon fiber composites have a much higher strength-to-weight ratio and stiffness-to-weight ratio than high-strength steel. This means a component made from carbon fiber can be both stronger and significantly lighter than an equivalent steel part. However, in an absolute sense, a thick, solid piece of steel may have higher overall tensile strength than a thin carbon laminate. The key advantage of carbon fiber is its ability to provide immense strength without the penalty of heavy weight.

Why is carbon fiber so expensive in automotive applications?

The high cost stems from multiple factors: the energy-intensive process of creating the carbon fiber precursor and converting it into filaments; the complex, often slow, and labor-intensive manufacturing processes like layup and autoclave curing; and the high cost of the epoxy resins and other raw materials. Furthermore, quality control is critical and requires sophisticated equipment and expertise. While automation and new technologies are bringing costs down, it remains a premium material. Companies focused on integrated manufacturing, like Jiangyin Dongli New Materials Technology Co., Ltd., work to optimize these processes to improve cost-effectiveness for technical sectors.

Can carbon fiber car parts be repaired?

Yes, damaged carbon fiber parts can often be repaired, but it is a specialized skill very different from metal repair. The process involves assessing the extent of the damage, carefully removing the damaged fibers and resin, and then bonding new, pre-cured patches or performing a wet layup with new fabric and resin, followed by curing. The repair must restore both the structural integrity and the aesthetic surface. For critical structural components, replacement is often recommended over repair to ensure safety.

What are the main disadvantages of using carbon fiber in mass-produced cars?

The primary disadvantage is cost, as detailed above. Other challenges include longer production cycle times compared to metal stamping, difficulty in recycling composite parts at end-of-life, and susceptibility to UV degradation if not properly coated (the resin can yellow and weaken). For these reasons, its use in mass-produced cars is currently limited to select high-value or critical performance components, though research into overcoming these hurdles is ongoing.

How does the choice of weave pattern affect the final part's properties?

The weave pattern is a fundamental driver of the composite's behavior. A plain weave offers balanced properties in all directions but is less drapeable. A twill weave provides better conformability to complex molds and is the standard for many visible automotive parts. A satin weave offers the highest drapeability and fiber-dominated mechanical properties, ideal for deeply contoured structural parts. Unidirectional (UD) fabric allows engineers to place strength precisely where it's needed most, optimizing weight and performance, but requires multiple layers at different angles to handle loads from all directions. The choice is a strategic trade-off between aesthetics, manufacturability, and mechanical requirements.

English

English  中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt