In the world of advanced composite materials, few combinations are as powerful or as sought-after as Carbon Fiber Woven Aramid Fabric. This hybrid material represents the pinnacle of engineering, merging the unparalleled tensile strength of aramid fibers with the exceptional stiffness and lightweight properties of carbon fiber. For engineers, designers, and hobbyists seeking to push the boundaries of performance, understanding this material is crucial. This comprehensive guide will delve deep into its properties, applications, and the key considerations for your next project, ensuring you have the knowledge to leverage its full potential.

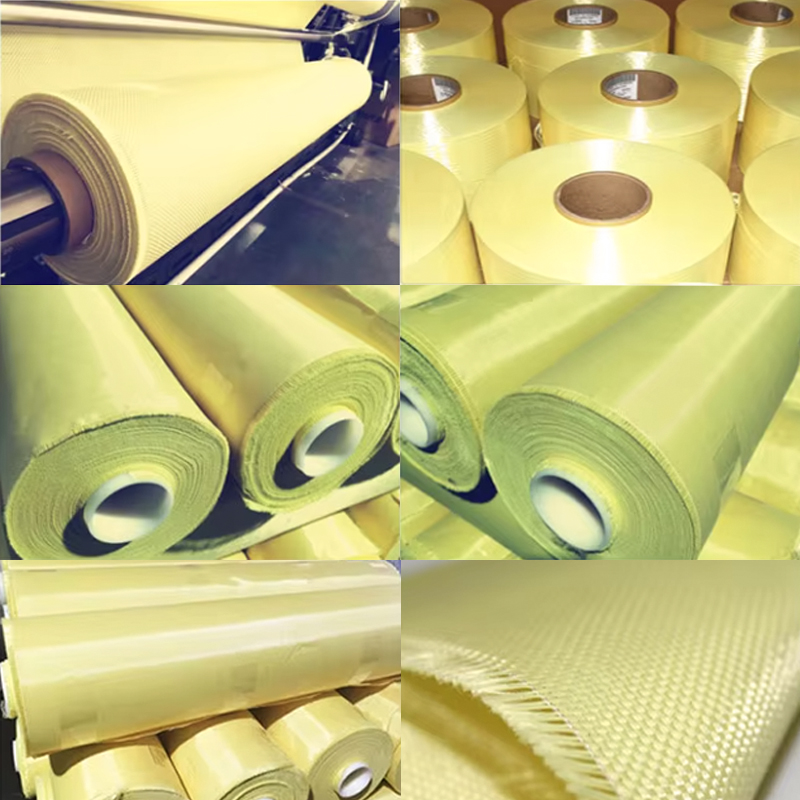

High Temperature Resistant And Flame Resistant Aramid Woven Fabric

What is Carbon Fiber Woven Aramid Fabric?

At its core, Carbon Fiber Woven Aramid Fabric is a hybrid textile where strands of carbon fiber and aramid (such as Kevlar®) are interlaced in a specific weave pattern. The result is a synergistic material that offers a superior balance of properties compared to its individual components. Carbon fiber provides high rigidity and a low weight-to-strength ratio, while aramid fiber contributes incredible impact resistance and toughness. This combination is particularly valuable in applications where a component must withstand both continuous structural loads and sudden impact events.

- Synergistic Performance: The fabric is engineered to capitalize on the strengths of both fibers, creating a composite that is more versatile than a pure carbon or pure aramid laminate.

- Weave Patterns: Common weaves like plain, twill, and satin can be used, each affecting the drapeability, surface finish, and mechanical properties of the final composite.

- Visual Distinction: The contrast between the black carbon fiber and the characteristic yellow (or other colors) of aramid creates a unique and recognizable aesthetic.

Key Properties and Advantages

The primary advantage of this hybrid fabric lies in its enhanced mechanical portfolio. It effectively bridges the gap between the brittle nature of pure carbon fiber and the lower compressive strength of pure aramid. This makes it an ideal choice for a wide array of demanding applications.

- High Impact Resistance: Aramid fibers are renowned for their ability to absorb and dissipate energy, making the composite highly resistant to impact and fragmentation.

- Excellent Strength-to-Weight Ratio: Carbon fiber ensures the component remains lightweight while providing significant structural stiffness.

- Damage Tolerance: The hybrid structure helps to contain damage, preventing cracks from propagating as easily as they might in a single-fiber composite.

- Vibration Damping: Aramid fibers contribute to better damping characteristics, which can be critical in aerospace and automotive applications.

Exploring the Top 5 Long-Tail Keyword Applications

To understand the practical uses of this material, it's best to examine specific scenarios and queries that professionals search for. These long-tail keywords reveal the nuanced needs and applications of Carbon Fiber Woven Aramid Fabric in the real world.

carbon fiber aramid hybrid fabric for automotive panels

The automotive industry, from high-performance racing to luxury supercars, is a prime beneficiary of this hybrid fabric. Using carbon fiber aramid hybrid fabric for automotive panels allows manufacturers to create body parts that are not only lightweight for improved speed and fuel efficiency but also exceptionally durable against road debris and minor impacts. The fabric's ability to be molded into complex shapes makes it perfect for doors, hoods, and splitters.

- Weight Reduction: Significantly reduces unsprung mass, improving handling, acceleration, and braking performance.

- Impact Protection: Offers superior resistance to stone chips and minor collisions compared to standard carbon fiber panels.

- Aesthetic Appeal: The distinctive woven pattern provides a high-tech, premium look that is highly desirable.

lightweight carbon kevlar fabric for drone frames

In the realm of unmanned aerial vehicles (UAVs), every gram matters. Lightweight carbon kevlar fabric for drone frames is the material of choice for serious drone builders. The rigidity of carbon fiber ensures stable flight and precise control, while the Kevlar component provides crucial crash resistance. A drone frame made from this material can survive hard landings that would shatter a pure carbon frame, saving on repair costs and downtime.

- Crash Resilience: Absorbs the energy from a crash, often resulting in a bent rather than a shattered frame.

- Flight Stability: The high stiffness minimizes frame flex, leading to more accurate data collection from onboard sensors and cameras.

- Longevity: Dramatically increases the operational lifespan of a professional or racing drone.

| Property | Pure Carbon Fiber Frame | Carbon/Kevlar Hybrid Frame |

| Weight | Very Low | Low |

| Stiffness | Very High | High |

| Impact Resistance | Low (Brittle) | Very High |

| Cost of Ownership | High (due to breakages) | Lower |

impact resistant composite fabric for personal armor

Personal protection is another critical field where this hybrid excels. When used as impact resistant composite fabric for personal armor, the material offers a multi-threat solution. The hard carbon fibers can help disperse the energy of a high-velocity impact, while the flexible, fibrous aramid layers work to catch and deform the projectile, significantly enhancing ballistic and stab protection in a lightweight package.

- Multi-Threat Defense: Effective against a range of threats, including fragmentation and blunt force trauma.

- Wearer Mobility: The reduced weight compared to traditional steel plates allows for greater mobility and reduced fatigue.

- Structural Rigidity: Helps armor plates maintain their shape and integrity after an impact.

woven carbon and aramid material for boat hulls

The marine environment demands materials that can withstand constant stress, impact, and the corrosive effects of saltwater. Utilizing woven carbon and aramid material for boat hulls results in vessels that are lighter, faster, and more fuel-efficient. More importantly, the aramid component provides exceptional resistance to impact damage from floating debris or docking mishaps, a common weakness of pure carbon fiber hulls.

- Hydrodynamic Efficiency: A stiffer hull flexes less in the water, reducing drag and increasing speed.

- Damage Containment: Helps prevent small impacts from developing into large cracks that could compromise the vessel's integrity.

- Corrosion Resistance: Both carbon and aramid fibers are inherently resistant to corrosion, unlike metals.

high strength carbon aramid weave for bicycle frames

The cycling world is perpetually chasing the holy grail of a frame that is light, stiff, and comfortable. A high strength carbon aramid weave for bicycle frames brings engineers closer to this ideal. The carbon fiber delivers the responsive, efficient power transfer that competitive cyclists demand, while the integrated aramid fibers add a layer of vibration damping and impact resistance, protecting the frame from damage and providing a slightly more forgiving ride on rough surfaces.

- Ride Quality: Improved vibration damping reduces rider fatigue on long journeys.

- Durability: Increased resistance to impacts from potholes or crashes, a key concern for gravel and mountain bikes.

- Design Freedom: Allows for the creation of more ambitious and aerodynamically optimized frame shapes.

| Frame Material | Stiffness | Comfort | Impact Resistance |

| Aluminum | High | Low | Medium |

| Standard Carbon Fiber | Very High | Medium | Low |

| Carbon/Aramid Hybrid | High | High | Very High |

FAQ

What is the difference between carbon fiber and carbon fiber woven aramid fabric?

The fundamental difference lies in composition and performance. Pure carbon fiber composites are exceptionally stiff and light but can be brittle, making them susceptible to cracking upon sharp impact. Carbon Fiber Woven Aramid Fabric is a hybrid that incorporates aramid fibers, which are exceptionally tough and impact-resistant. Think of it as carbon fiber providing the "bones" (structural stiffness) and aramid providing the "muscles" (toughness and damage tolerance). The resulting material sacrifices a minuscule amount of pure stiffness for a massive gain in durability and impact resistance.

Is carbon aramid fabric better for impact than pure carbon fiber?

Yes, unequivocally. This is the primary reason for creating the hybrid. Aramid fibers possess a high strain-to-failure rate, meaning they can stretch and absorb a tremendous amount of energy before breaking. In a composite, when an impact occurs, the aramid fibers yield and deform, absorbing the energy and preventing the more brittle carbon fibers from immediately fracturing. This makes carbon fiber woven aramid fabric vastly superior for any application where impact, abrasion, or shock loading is a concern, such as in drone frames, protective equipment, and automotive components.

How do you choose the right weave pattern for a project?

Selecting a weave pattern is a critical decision that balances aesthetics, mechanical properties, and manufacturability. The three most common weaves for Carbon Fiber Woven Aramid Fabric are:

- Plain Weave: The most stable and tightest weave. It offers good integrity but is less drapable, making it better for flat or simple curved panels.

- Twill Weave (2x2, 4x4): Characterized by a diagonal rib pattern. It offers a good compromise, with better drapeability than plain weave and a very attractive, classic composite look.

- Satin Weave (4-harness, 8-harness): The most drapable and pliable weave, ideal for complex, deeply contoured molds. It produces a very smooth surface finish but can be less stable than twill or plain.

Your choice should be guided by the complexity of your part's geometry and the desired surface finish.

Can carbon aramid fabric be used for high-temperature applications?

This depends on the specific aramid fiber and the resin system used. Standard aramids like Kevlar® 29/49 have a continuous service temperature around 150-160°C (300-320°F). While the carbon fiber component can withstand much higher temperatures, the aramid fibers will begin to degrade, limiting the overall composite's performance. For high-temperature applications, it is crucial to consult the datasheets for both the fibers and the matrix resin. In such cases, a pure carbon fiber or a carbon/glass hybrid might be a more suitable choice than carbon fiber woven aramid fabric.

English

English  中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt