Woven carbon fabric is a crucial high-performance material. This document provides a comprehensive analysis of its advanced properties and diverse industrial applications, exploring how its structure and manufacturing processes enable its superior performance.

Structure and Manufacturing of Woven Carbon Fabric

Woven Carbon Fabric: A Comprehensive Analysis from Structure to Application

1.1 Properties and Classification of Carbon Fibers

Carbon fibers are composed of carbon atoms arranged in a graphite crystal structure, giving them unique properties. They are primarily classified by their mechanical performance:

- High-Tensile Strength Carbon Fibers: With tensile strengths typically above 4,000 MPa, these fibers are ideal for applications requiring high load-bearing capacity, such as aircraft wings and pressure vessels.

- High-Modulus Carbon Fibers: These fibers, with tensile moduli above 300 GPa, are exceptionally stiff. They are essential for applications requiring precise dimensional stability, including satellite antennas and precision instruments.

- Intermediate-Modulus Carbon Fibers: Balancing high strength and stiffness, these fibers are widely used in aerospace and high-end sporting goods.

1.2 Weaving Techniques for Woven Carbon Fabric

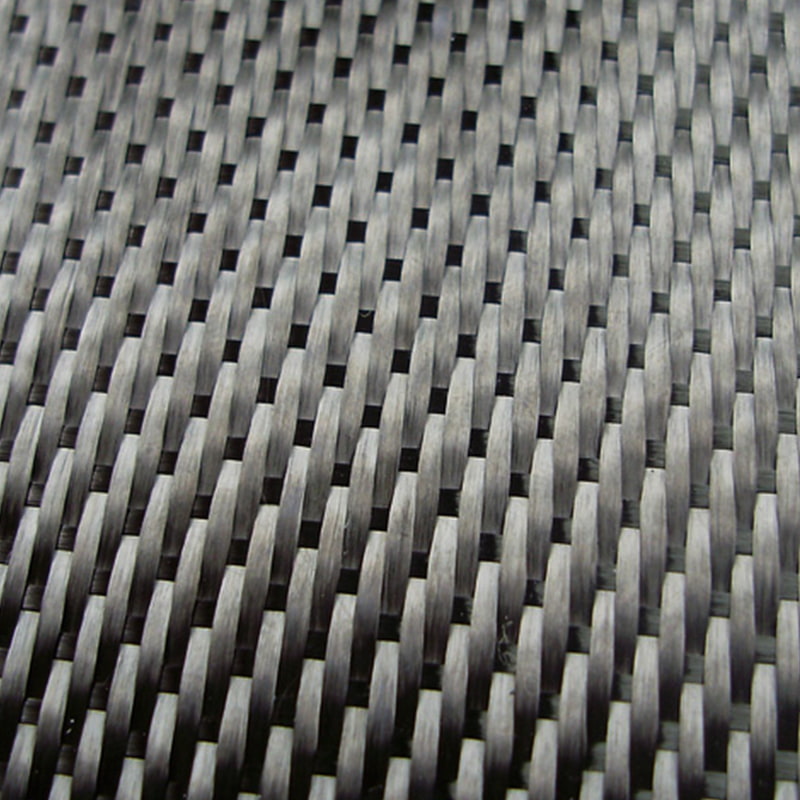

The weaving method significantly influences the mechanical properties, appearance, and processability of the final woven carbon fabric.

| Weave Type | Structural Characteristics | Performance Advantages | Application Examples |

|---|---|---|---|

| Plain Weave | The simplest weave with a one-over, one-under pattern. | High stability, good dimensional stability, and resistance to deformation. | Architectural reinforcement, industrial filters, general-purpose composites. |

| Twill Weave | Features a diagonal pattern with two-over, two-under, or three-over, three-under intersections. | High conformability, easy to drape and shape for complex parts, balanced mechanical properties. | Aerospace structures, automotive body panels, sports equipment. |

| Satin Weave | Characterized by a smooth surface where warp or fill yarns float over multiple intersecting yarns. | Smooth surface, excellent resin wet-out, higher strength, but less structural stability. | Aircraft skins, high-performance composites, aesthetic parts. |

1.3 Preparation of Fabric Preforms

A fabric preform is created by cutting, stacking, and fixing layers of woven carbon fabric into a shape close to the final product. This process is crucial for manufacturing high-performance composites, as it ensures accurate fiber orientation and structural integrity. Preforms simplify subsequent molding processes, reducing production time and cost, especially for complex geometries.

Advanced Properties of Woven Carbon Fabric

2.1 Mechanical Properties

The superior performance of woven carbon fabric stems from the inherent properties of carbon fibers and its woven structure.

- High Strength and Stiffness: Carbon fibers' atomic structure provides exceptional tensile strength and modulus. Woven carbon fabric can be several times stronger than steel of the same weight, with a much higher stiffness, resulting in minimal deformation under load.

- Fatigue Resistance: Woven carbon fabric performs exceptionally well under cyclic loading. Its fiber-matrix interface and woven structure effectively disperse stress, delaying crack initiation and propagation.

- Impact Resistance: When subjected to impact, woven carbon fabric absorbs energy through mechanisms like fiber breakage and delamination, making it ideal for protective gear and crash structures.

Here is a comparison of typical mechanical properties between woven carbon fabric and traditional materials:

| Material Type | Density (g/cm³) | Tensile Strength (MPa) | Tensile Modulus (GPa) |

|---|---|---|---|

| Woven Carbon Fiber | 1.5 - 1.8 | 400 - 1000 | 70 - 150 |

| High-Strength Steel | 7.85 | 400 - 800 | 200 - 210 |

| Aluminum Alloy | 2.7 | 250 - 500 | 70 - 80 |

2.2 Thermal and Electrical Properties

In addition to its excellent mechanical properties, woven carbon fabric also has unique thermal and electrical advantages.

- High Thermal Resistance: Carbon fibers maintain structural integrity at extremely high temperatures, making woven carbon fabric suitable for aerospace engine components and rocket nozzles.

- Electrical Conductivity: Woven carbon fabric can function as an electrical conductor, allowing for applications in antistatic components, electromagnetic shielding, and heating elements.

Industrial Applications of Woven Carbon Fabric

Woven carbon fabric is indispensable in several key industries, particularly where lightweighting, high strength, and durability are paramount.

3.1 Aerospace

- Airframe Structures: Woven carbon fabric is used to manufacture primary load-bearing structures like aircraft wings, vertical stabilizers, and fuselages, significantly reducing aircraft weight and improving fuel efficiency.

- Satellite and Rocket Components: Woven carbon fabric is used for satellite frames, solar panel brackets, and rocket fairings, providing high stiffness and low weight for space applications.

3.2 Automotive Industry

- Body and Chassis: High-performance cars and electric vehicles use woven carbon fiber composites for body panels and chassis to achieve superior stiffness and lightweighting, enhancing handling and safety.

- Racing Components: In motorsport, woven carbon fabric is the material of choice for monocoques and crash structures in Formula 1 cars, providing unmatched strength and impact resistance.

3.3 Sports and Leisure Equipment

- High-Performance Gear: Woven carbon fabric is used to create lighter, stiffer, and more responsive equipment like tennis rackets, golf clubs, and bicycle frames.

- Protective Equipment: It is also used in helmets and protective gear for sports like racing and skiing, offering maximum protection with minimal weight.

3.4 Construction and Civil Engineering

- Structural Reinforcement: Woven carbon fabric can be externally bonded to reinforce aging bridges, columns, and beams, significantly enhancing their load-bearing capacity and lifespan.

- Seismic Engineering: Carbon fiber reinforcement techniques improve the ductility and seismic resistance of structures.

Woven carbon fabric has established itself as an essential advanced material due to its exceptional properties, including high strength, stiffness, light weight, and superior fatigue and impact resistance. It plays a critical role in driving innovation across aerospace, automotive, sports, and civil engineering.

The material's strength-to-weight ratio is particularly impressive when compared to traditional materials:

| Material Type | Density (g/cm³) | Tensile Strength (MPa) | Strength-to-Weight Ratio (MPa·cm³/g) |

|---|---|---|---|

| Woven Carbon Fiber | 1.5 - 1.8 | 400 - 1000 | 222 - 667 |

| High-Strength Steel | 7.85 | 400 - 800 | 51 - 102 |

| Aluminum Alloy | 2.7 | 250 - 500 | 93 - 185 |

The table highlights that the strength-to-weight ratio of woven carbon fiber far surpasses that of conventional metals, explaining its demand in performance-driven applications.

Looking ahead, the development of woven carbon fabric will focus on integrating new technologies. This includes advanced weaving techniques for complex structures, the creation of smart carbon fiber fabrics with built-in sensing or self-healing capabilities, and the development of more efficient and sustainable composite molding processes.

Companies like Jiangyin Dongli New Materials Technology Co., Ltd. exemplify this forward-thinking approach. By integrating material innovation with engineering expertise and controlling the entire process—from weaving and prepreg production to advanced molding technologies like autoclave, RTM, and PCM—they are unlocking the full potential of woven carbon fabric. This one-stop manufacturing capability allows them to deliver high-quality, customized solutions for industries like aerospace, automotive, and sports equipment development.

Corrosion-Resistant And Drug-Resistant Satin Carbon Fiber Weave Fabric

English

English  中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt