A Deep Dive into an Advanced Material

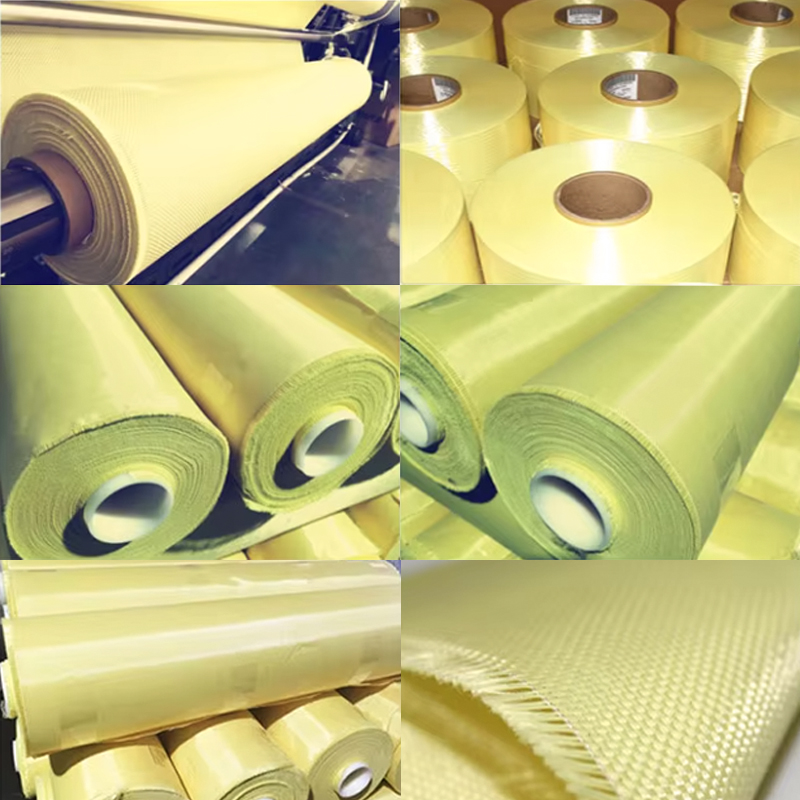

Jiangyin Dongli New Materials Technology Co., Ltd. specializes in the development and manufacturing of high-performance fiber composite materials. Operating from a 32,000-square-meter industrial complex with precision-controlled environments, our company integrates material innovation with engineering expertise to serve technical sectors like aerospace, automotive manufacturing, and sports equipment development. This article will guide you through the essential maintenance practices for products made from Carbon Fiber Woven Aramid Fabric, a material we at Jiangyin Dongli understand deeply, to ensure their longevity and performance.

As a one-stop factory with full process control, our capabilities include R&D and production of high-performance fiber fabrics through advanced weaving and prepreg processes, as well as composite products utilizing state-of-the-art technologies like autoclave, RTM, and WCM. The products born from these processes, such as those made from Carbon Fiber Woven Aramid Fabric, require specific care to maintain the superior properties that make them so valuable. By following the guidelines below, you can preserve the structural integrity and aesthetic appeal of your high-tech equipment for years to come.

Effective Cleaning and Routine Care

Proper and consistent cleaning is the first and most critical step in maintaining any product crafted from Carbon Fiber Woven Aramid Fabric. This hybrid material, known for its unique combination of strength and impact resistance, performs best when kept free of contaminants that could compromise its surface integrity over time. Understanding the correct methods can prevent long-term damage and keep the material's aesthetic and structural properties intact.

Best Practices for a Clean Surface

Adhering to a gentle cleaning regimen is essential. Unlike more rugged materials, abrasive cleaners or harsh scrubbing can damage the delicate fibers and resin matrix. The right approach involves using specific products and techniques to lift dirt without compromising the material's integrity.

-

Gentle Cleaning Agents

For routine cleaning, a mild soap solution and lukewarm water are the best choices. It’s important to avoid any cleaners with harsh chemicals like ammonia or bleach, which can degrade the resin that binds the fibers. A simple pH-neutral soap is sufficient for removing most surface dirt and grime.

-

Proper Cleaning Techniques

Use a soft, non-abrasive cloth or sponge for application. Gently wipe the surface in smooth, circular motions. Avoid excessive pressure. After cleaning, rinse the product with clean water and dry it completely with a microfiber towel to prevent water spots.

-

Avoiding Common Mistakes

One of the most common mistakes is not knowing how to clean carbon fiber aramid composite correctly. Do not use pressure washers, wire brushes, or scouring pads, as these will scratch the surface and potentially fray the aramid fibers. Furthermore, do not leave the product to air-dry in direct sunlight, as prolonged UV exposure can cause the resin to yellow and become brittle.

Understanding Material Properties for Better Maintenance

To truly master the maintenance of this advanced composite, you must understand its inherent properties. The Carbon Fiber Woven Aramid Fabric is a hybrid for a reason, blending the high stiffness of carbon with the exceptional toughness of aramid fibers. This unique combination dictates a specific care approach that differs from single-material composites.

Comparing Carbon Fiber Aramid vs Kevlar for Care

While aramid fibers are often colloquially referred to as “Kevlar,” understanding the key differences in how the pure aramid material and a hybrid composite behave is crucial for effective care. The combination of carbon and aramid affects the material's rigidity, impact resistance, and susceptibility to environmental factors.

| Property | Hybrid (Carbon Fiber Woven Aramid Fabric) | Pure Aramid (e.g., Kevlar) |

| Impact Resistance | High; aramid absorbs energy and prevents catastrophic failure. | Very high; excellent at stopping projectiles and absorbing blunt force. |

| Rigidity / Stiffness | Very high; carbon fibers provide exceptional stiffness. | Moderate; much more flexible and compliant. |

| Aesthetic Appearance | Distinctive woven pattern; can be finished with a clear coat. | Often has a soft, felt-like surface; less common in aesthetic applications. |

| Environmental Sensitivity | More resistant to moisture due to the carbon component, but UV sensitive. | Can absorb moisture, which may affect performance; also UV sensitive. |

The Role of Carbon Fiber Aramid Fabric Tensile Strength in Longevity

The impressive carbon fiber aramid fabric tensile strength is a result of the two fibers working together. Carbon fibers provide the material's primary load-bearing capability, while the aramid fibers prevent crack propagation and absorb energy, making the material highly resilient. To preserve this strength, you must:

-

Avoid Stress Concentrations

Do not clamp or fasten the product with excessive force in one specific area, as this can create a weak point over time, potentially leading to delamination or fracture.

-

Prevent Scratches and Deep Abrasions

While the aramid component offers good abrasion resistance, deep scratches can compromise the resin-fiber bond and expose the reinforcing fibers to environmental degradation.

-

Monitor for Micro-Cracks

After a significant impact, inspect the surface carefully. Even if the material has not failed, microscopic cracks in the resin can form. Timely assessment and repair are key to maintaining its structural integrity.

Handling Damage and When to Seek a Professional

Even with the best care, composite products can sustain damage. Knowing when and how to address minor issues yourself versus when to seek a professional for more complex repairing carbon fiber aramid composite is critical for safety and performance.

Practical Steps for Repairing Carbon Fiber Aramid Composite

-

Assessing Minor vs. Major Damage

Minor damage typically includes cosmetic scratches or shallow abrasions that do not go through the top resin layer. Major damage, in contrast, involves delamination, deep cracks that expose the fibers, or structural failure.

-

Steps for Simple Patch Repairs

For minor cosmetic damage, a simple epoxy or clear coat repair kit can be used. Clean the area, lightly sand the surrounding surface, apply a thin layer of the resin, and let it cure as per the instructions. This seals the surface and protects the fibers underneath.

-

When to Contact a Specialist

If you see signs of structural damage, such as a soft or spongy spot, a full-thickness crack, or if the product has been involved in a high-impact event, do not attempt a DIY fix. A professional composite repair shop has the tools and expertise to properly assess and repair the damage, ensuring the product's safety and performance are fully restored.

Securing the Future of Your Product

Long-term care extends beyond cleaning and repairs. Proper storage is paramount to ensuring the aramid carbon fiber hybrid material durability. Environmental conditions can degrade the material over time, reducing its lifespan and performance.

Ensuring Aramid Carbon Fiber Hybrid Material Durability Through Proper Storage

-

Environmental Factors to Consider

Keep the product away from direct sunlight and extreme temperatures. UV rays can cause the resin to become yellow and brittle, and extreme heat can lead to delamination. Store it in a cool, dry place.

-

Best Practices for Long-Term Storage

When storing the product for an extended period, ensure it is clean and dry. Avoid placing heavy objects on top of it, which could cause stress concentrations. If possible, store it in a hanging position or on a rack that supports its full structure evenly.

High Temperature Resistant And Flame Resistant Aramid Woven Fabric

English

English  中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt