Why Carbon Fiber Composite Panels have become the material of choice for modern industrial design?

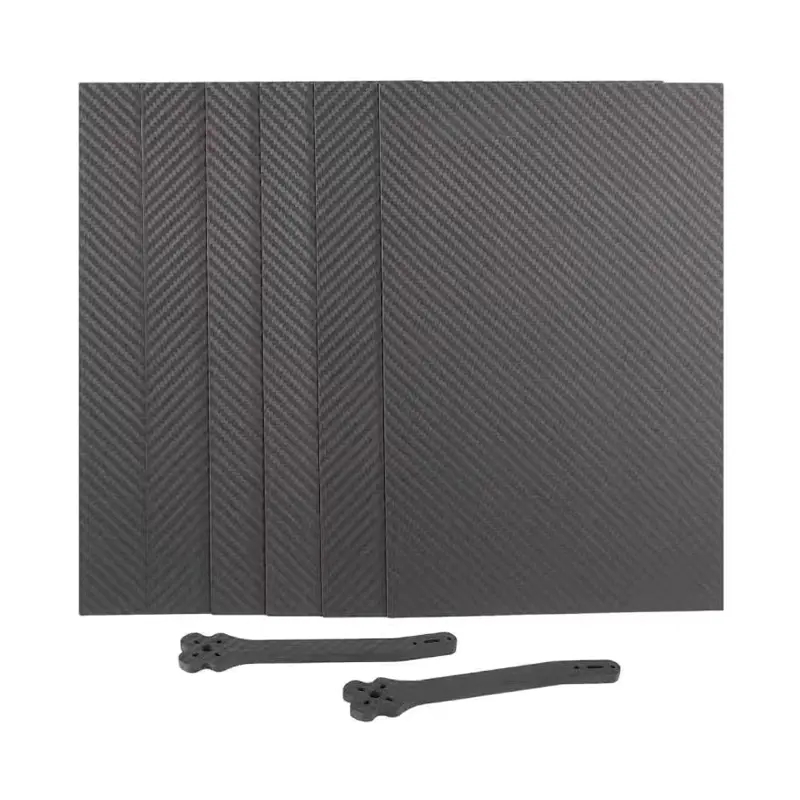

Carbon Fiber Composite Panels are made of carbon fiber and high-performance resin. With this unique structure, carbon fiber composite materials have shown obvious advantages over traditional materials in all aspects. First of all, the strength of carbon fiber itself is several times that of steel, but its weight is only about one-fourth of steel. This feature enables Carbon Fiber Composite Panels to significantly reduce the weight of the overall structure. Lightweighting can not only improve the performance and efficiency of equipment and reduce energy consumption, but also reduce manufacturing and transportation costs. In high-end fields such as aerospace, automobiles, and racing, weight reduction is of immeasurable value for improving energy efficiency and performance.

Although traditional metal materials have advantages in strength, they often bring additional energy consumption and burden due to their heavy weight. In contrast, Carbon Fiber Composite Panels provide a more ideal solution. By replacing traditional materials, carbon fiber composite panels can not only enhance the load-bearing capacity of the structure, but also reduce unnecessary weight and optimize equipment design. Therefore, when facing extremely demanding engineering projects, carbon fiber composite materials have become the most popular choice.

Another major advantage of carbon fiber composite materials is their excellent corrosion resistance. Traditional metal materials are susceptible to oxidation, corrosion or rust in many harsh environments, which can lead to the degradation of material performance and even affect the stability of the entire structure. Carbon Fiber Composite Panels have extremely high chemical stability. They can maintain their physical properties for a long time in various high temperature, high humidity or chemical corrosion environments, and resist the erosion of most chemicals.

This anti-corrosion property makes carbon fiber composites perform well in many fields with strict corrosion resistance requirements. Whether it is equipment exposed to marine environments or industrial equipment that needs to face high temperature or humid environments for a long time, carbon fiber composites can effectively extend the service life, reduce maintenance and replacement frequency, and thus reduce overall operating costs.

In addition, the resistance of carbon fiber composites to chemicals makes it have a wide range of application potential in many demanding industries. Its superior corrosion resistance can bring a longer life cycle to equipment, improve the reliability of the overall system, and reduce the potential risk of failure due to corrosion.

Another feature that makes Carbon Fiber Composite Panels stand out is its excellent thermal stability and resistance to thermal expansion. When facing high temperature environment, traditional metal materials often deform, melt or other damage, while carbon fiber composite materials can maintain good stability at high temperature and avoid performance degradation caused by thermal expansion or high temperature.

The thermal stability of carbon fiber composite materials gives it significant advantages in many high temperature working environments. For example, in the fields of aerospace, automobiles and racing, the parts of the equipment need to operate for a long time under high temperature, strong pressure and harsh conditions. The use of Carbon Fiber Composite Panels can effectively reduce the material deformation caused by temperature fluctuations, thereby improving the reliability and safety of the equipment.

The thermal expansion resistance of carbon fiber composite materials enables it to maintain its morphology and structural integrity in high temperature environments. When traditional metal materials face high temperatures, they may expand or deform, affecting the overall function and structure. Carbon fiber composite materials can ensure safe use under extreme conditions due to their high temperature stability.

With the advancement of technology and the continuous changes in industrial needs, modern industrial design pays more and more attention to the performance advantages of materials and their adaptability in specific environments. Carbon Fiber Composite Panels have become the preferred material for more and more industries due to its multiple advantages such as lightweight, high strength, corrosion resistance and thermal stability.

First of all, the lightweight characteristics of carbon fiber composite materials give it an incomparable advantage in the fields of automobiles and aerospace. By reducing the weight of the structure, carbon fiber composites can help improve the overall performance of the equipment, enhance energy efficiency, and reduce manufacturing costs. Especially in some applications that require high strength and low weight, the application of carbon fiber composite panels has become the key to design innovation.

Secondly, the corrosion resistance and thermal stability of carbon fiber composites make it perform well in some demanding environments. These characteristics not only provide long-term protection for the equipment, but also greatly improve the safety and reliability of the structure, reduce the frequency of maintenance and replacement, and thus reduce the subsequent operating costs.

English

English

中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt