- 1 1. Cryogenic Storage: Inhibiting the Curing Reaction

- 2 2. Managing Out-Life and Tack Degradation

- 3 3. Moisture Contamination and Thawing Protocols

- 4 4. Dongli New Materials: Precision Controlled Production

- 5 5. Frequently Asked Questions (FAQ)

- 5.1 1. How do I know if the out-life of epoxy prepreg has expired?

- 5.2 2. Can I re-freeze carbon epoxy prepreg to stop the out-life clock?

- 5.3 3. What happens if I use a carbon fiber prepreg with low tack?

- 5.4 4. Why is a cleanroom environment necessary for handling carbon fiber prepreg?

- 5.5 5. Is carbon fiber prepreg storage temperature different for different resin systems?

- 6 Industry References

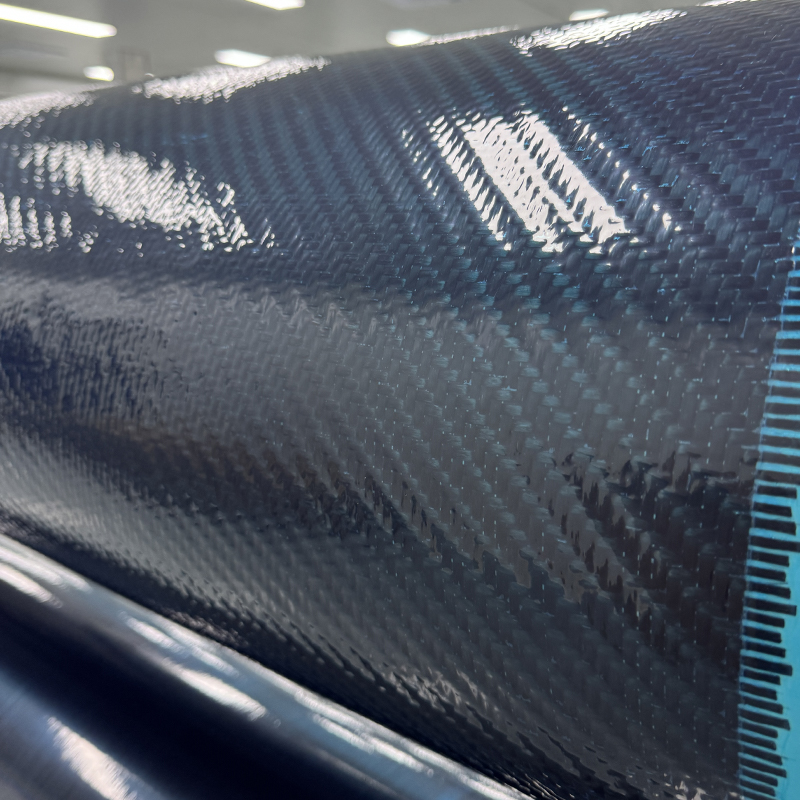

In the high-precision world of advanced composites, carbon epoxy prepreg represents the pinnacle of material efficiency, combining structural reinforcement with a pre-catalyzed resin system. However, the reactive nature of epoxy resins makes these materials highly sensitive to environmental variables. To ensure the highest mechanical performance in aerospace and automotive applications, maintaining the material's "tack" (stickiness) and "drape" (conformability) is paramount. Jiangyin Dongli New Materials Technology Co., Ltd. operates from a 32,000-square-meter industrial complex equipped with 100,000-grade purification zones and climate-regulated workshops to guarantee the integrity of our carbon epoxy prepreg products. This guide explores the technical necessities of carbon fiber prepreg storage temperature and the management of out-life to prevent premature resin advancement.

1. Cryogenic Storage: Inhibiting the Curing Reaction

The epoxy resin in a prepreg is in a "B-stage" state—partially cured but still chemically reactive. At room temperature, the cross-linking process continues slowly, which eventually leads to the material becoming stiff and losing its ability to adhere to mold surfaces. To halt this, carbon epoxy prepreg must be stored in specialized freezers. While standard materials might survive briefly at higher temperatures, storing carbon fiber prepreg in freezers at -18°C is the industry standard to ensure a shelf life of 6 to 12 months. Any deviation in storage temperature can lead to "resin advancement," significantly reducing the quality of the final consolidated part.

Comparison: Storage Temperature vs. Material Shelf Life

As temperature increases, the chemical reaction rate accelerates exponentially, drastically shortening the time the material remains viable for production.

| Storage Condition | Average Temperature | Estimated Shelf Life |

| Deep Freeze | -18°C (0°F) | 6 - 12 Months |

| Chilled Storage | +4°C (40°F) | 1 - 3 Months |

| Room Temperature | +21°C (70°F) | 5 - 20 Days (Out-life) |

2. Managing Out-Life and Tack Degradation

Out-life refers to the accumulated time carbon epoxy prepreg spends outside of the freezer. This is the most critical factor for technicians during the layup process. Once the material reaches room temperature, the out-life of epoxy prepreg begins to tick down. Tack is the ability of the prepreg to stick to itself and the tool, which is essential for complex geometries. Drape refers to the material's ability to fold and conform to contours without fiber bridging. If the carbon fiber prepreg out-life is exceeded, the resin becomes too viscous, leading to poor interlaminar bonding and potential voids during autoclave or PCM processing.

Comparison: Tack and Drape Characteristics over Time

The physical handling characteristics of the material degrade steadily as the resin progresses toward its gel point at room temperature.

| Time at Room Temp | Tack Level | Drape Capability |

| Day 1-3 | High / Aggressive | Excellent (High Conformability) |

| Day 7-10 | Medium / Diminishing | Good (Some stiffness) |

| Post Out-Life | Dry / Non-adhesive | Brittle (Risk of fiber breakage) |

3. Moisture Contamination and Thawing Protocols

One of the most overlooked carbon fiber prepreg handling best practices is the thawing protocol. When carbon epoxy prepreg is removed from the freezer, it is significantly colder than the ambient dew point. If the protective sealed bag is opened before the roll reaches room temperature, moisture will condense directly onto the resin surface. This moisture becomes trapped during layup and vaporizes during the cure cycle, resulting in high porosity and delamination. Jiangyin Dongli New Materials emphasizes the use of climate-regulated workshops to manage this transition, ensuring that the carbon fiber prepreg moisture sensitivity does not compromise aerospace-grade components.

4. Dongli New Materials: Precision Controlled Production

As a one-stop factory, Jiangyin Dongli New Materials Technology Co., Ltd. integrates full process control from weaving to prepreg production. Our facility serves technical sectors through a variety of composite manufacturing technologies, including autoclave, RTM, and WCM prepreg processes. Our 100,000-grade purification zones ensure that no airborne contaminants interfere with the tack of our carbon epoxy prepreg. By combining engineering expertise with rigorous environmental monitoring, we provide materials that maintain their prepreg drape and conformability for the most demanding sports equipment and automotive applications.

Critical Storage and Handling Requirements:

- Vapor Barrier Integrity: Always keep prepreg sealed in moisture-proof bags during the thawing phase.

- Time Tracking: Maintain a logbook for every roll of

carbon epoxy prepreg to track cumulative out-life. - First-In, First-Out (FIFO): Rotate stock to ensure the oldest material is used before its shelf life expires.

- Temperature Monitoring: Use calibrated data loggers inside freezers to detect power failures or temperature spikes.

5. Frequently Asked Questions (FAQ)

1. How do I know if the out-life of epoxy prepreg has expired?

The most obvious signs are a loss of tack and increased stiffness (loss of drape). In a lab setting, a Differential Scanning Calorimetry (DSC) test can determine the "degree of cure" to see if the resin has advanced too far.

2. Can I re-freeze carbon epoxy prepreg to stop the out-life clock?

Yes, re-freezing slows the reaction significantly, but it does not "reset" the clock. You must track the total cumulative time the material spends at room temperature.

3. What happens if I use a carbon fiber prepreg with low tack?

Low tack makes it difficult to keep plies in place on vertical or complex tool surfaces. It often results in "spring-back" or fiber bridging, which creates structural weak points in the finished part.

4. Why is a cleanroom environment necessary for handling carbon fiber prepreg ?

Dust, oils, and skin cells can act as release agents. Because prepregs are inherently sticky, they attract contaminants that can cause delamination or surface defects during the curing process.

5. Is carbon fiber prepreg storage temperature different for different resin systems?

Yes. While -18°C is standard for most epoxies, some high-temperature resins or cyanate esters may have specific requirements. Always consult the Technical Data Sheet (TDS) provided by Jiangyin Dongli New Materials.

Industry References

- ASTM D3529: Standard Test Method for Resin Solids Content of Carbon Fiber-Epoxy Prepreg.

- CMH-17: Composite Materials Handbook - Guidelines for Characterization of Structural Materials.

- ISO 14644-1: Classification of Air Cleanliness for Cleanrooms and Associated Controlled Environments.

- Jiangyin Dongli Internal Engineering Standard: Environmental Management for High-Performance Fiber Composites (2026).

English

English  中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt