Traditional pipe fittings, often made from metals like steel or aluminum, have long been favored for their strength. However, they come with limitations: weight, susceptibility to corrosion, and complexity in shaping. Composite carbon fiber, by contrast, offers a superior alternative. Its high strength-to-weight ratio, combined with exceptional fatigue resistance and chemical inertness, makes it ideal for applications demanding both performance and longevity. Whether it's routing hydraulic fluids in aircraft, optimizing fuel lines in race cars, or enhancing the ergonomics of sports gear, carbon fiber fittings deliver unmatched advantages.

Unparalleled Strength and Lightweight Design: Carbon fiber's intrinsic properties allow for fittings that are 50% lighter than steel yet capable of withstanding extreme pressures and temperatures. This weight reduction translates to fuel efficiency in automotive systems and payload optimization in aerospace applications.

Corrosion Resistance: Unlike metals, carbon fiber does not rust or degrade in harsh environments, ensuring reliable performance in marine, chemical, or outdoor settings.

Design Flexibility: The material's moldability enables complex geometries, allowing engineers to tailor fittings to specific spatial or functional requirements without compromising structural integrity.

Thermal and Electrical Insulation: Carbon fiber's low thermal conductivity and electrical resistivity make it suitable for applications requiring insulation, such as cryogenic systems or electrical enclosures.

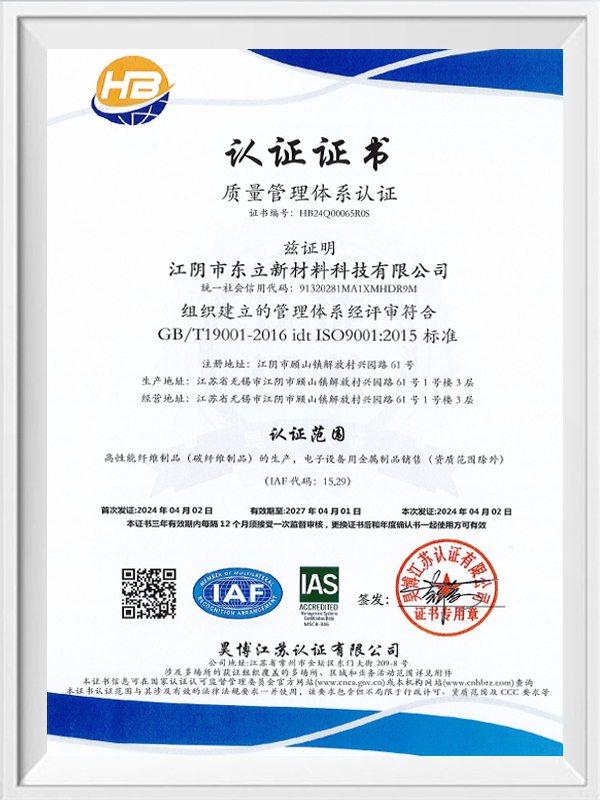

At the forefront of this revolution is Jiangyin Dongli New Materials Technology Co., Ltd., a one-stop factory with full process control. By integrating material innovation with engineering expertise, Dongli bridges the gap between raw material development and end-product manufacturing. Their capabilities span the entire value chain:

High-Performance Fiber Fabrics: Through advanced weaving and prepreg processes, Dongli produces fiber fabrics tailored for specific applications, ensuring optimal strength and flexibility.

Cutting-Edge Manufacturing Technologies: Utilizing autoclave, RTM (Resin Transfer Molding), RMCP (Resin Membrane Compression Process), PCM (Prepreg Compression Molding), WCM (Wet Compression Molding), and spraying technologies, the company crafts composite products with precision and efficiency.

Industry-Specific Solutions: Dongli's expertise extends to aerospace, automotive, and sports equipment development, where their fittings are critical to enhancing performance and reliability.

As industries increasingly prioritize sustainability and efficiency, composite carbon fiber pipe fittings are poised to become ubiquitous. Their ability to reduce weight, extend service life, and enable innovative designs aligns with global trends toward greener technologies. Companies like Jiangyin Dongli are not just adapting to this shift—they're driving it.

English

English

中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt