When a carbon fiber special-shaped part with a complex structure adopts the winding molding process, how to accurately control the winding angle and tension of the fiber to meet the mechanical performance requirements of different parts?

When a carbon fiber special-shaped part with a complex structure adopts the winding molding process, it is crucial to accurately control the winding angle and tension of the fiber to meet the mechanical performance requirements of different parts. The following are some methods to achieve precise control:

Precise control of winding angle

Precise mold design and modeling: Accurate mold design is required according to the complex structure and mechanical performance requirements of the special-shaped part. Use computer-aided design (CAD) software to establish a three-dimensional model of the special-shaped part to accurately depict the shape and size of each part. For example, for complex carbon fiber special-shaped parts used in the aerospace field, the mold design needs to take into account the stress of the aircraft under different flight conditions to ensure that different parts of the special-shaped part can withstand the corresponding load.

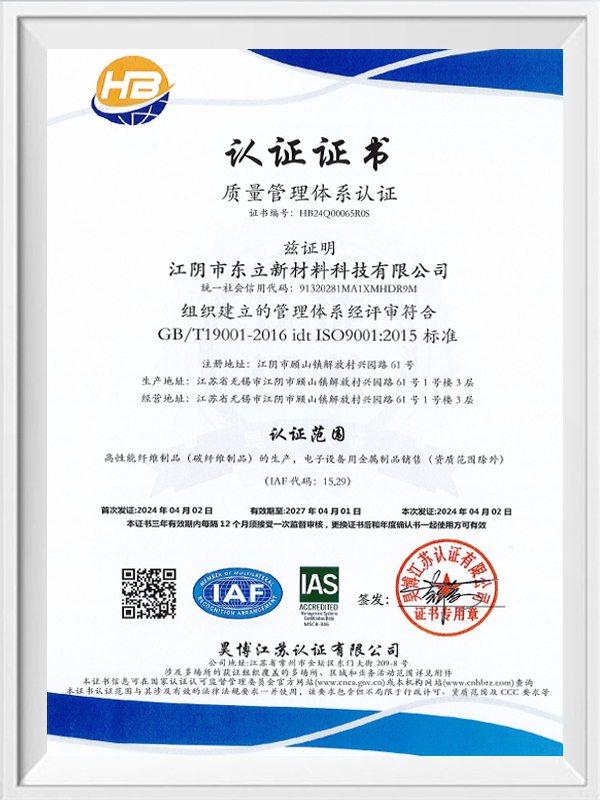

Advanced path planning algorithm: Based on the mold model, an advanced path planning algorithm is used to determine the winding path and angle of the fiber. Common algorithms include isotensoid winding algorithm, shortest path algorithm, etc. These algorithms can calculate the optimal winding angle distribution according to the mechanical performance requirements of different parts of the special-shaped part. For example, in high-performance automotive parts, for parts subject to greater bending stress, the path planning algorithm will design the corresponding winding angle so that the fiber can withstand the bending force to the greatest extent. The intelligent loom independently developed by Jiangyin Dongli New Materials Technology Co., Ltd. has innovative multi-axis and jacquard functions, which can provide customized patterns for specialized applications, which also implies that the company has certain technical capabilities in path planning and can achieve complex fiber winding path planning through the functions of intelligent looms.

Real-time monitoring and feedback system: During the winding process, high-precision angle monitoring sensors are installed to monitor the fiber winding angle in real time. Once an angle deviation is found, the feedback system will immediately transmit the information to the control system, and the control system will automatically adjust the motion parameters of the winding equipment according to the feedback information to correct the angle deviation. For example, in the development of sports equipment, for some special-shaped carbon fiber special-shaped parts, the real-time monitoring and feedback system can ensure the accuracy of the fiber winding angle, thereby ensuring the performance stability of the equipment during use.

Precise control of tension

Advanced tension control system: High-precision tension control devices such as magnetic powder brakes and pneumatic tension controllers are used. These devices can accurately control the tension of the fiber during the winding process according to the preset tension value. Taking the aerospace field as an example, for some key carbon fiber special-shaped parts, the mechanical properties they bear are extremely high. The advanced tension control system can ensure that the fiber maintains a stable tension during the winding process, thereby ensuring the strength and reliability of the special-shaped parts. Jiangyin Dongli New Materials Technology Co., Ltd. can produce fabrics with good uniformity and density through the tension control system independently developed by itself, which shows that the company has certain technical strength in tension control, and its tension control system can meet the requirements of different products for fiber tension control.

Accurate consideration of material properties: Different carbon fiber materials have different mechanical properties and tensile properties. When determining the tension control parameters, the characteristics of the carbon fiber material need to be accurately considered. For example, for high-strength carbon fiber materials, they can withstand greater tension, while for some carbon fiber materials with good flexibility but relatively low strength, tension control needs to be more refined.

Segmented tension control strategy: According to the mechanical performance requirements of different parts of the special-shaped parts, a segmented tension control strategy is adopted. In some key parts, such as stress concentration areas, the tension of the fiber is increased to improve the strength and bearing capacity of the part; while in some relatively minor parts, the tension is appropriately reduced to avoid fiber damage or material performance degradation due to excessive tension. For example, in some large carbon fiber special-shaped parts in the industrial field, the segmented tension control strategy can optimize the use of materials and reduce production costs while ensuring the overall mechanical properties.

Process optimization and quality control

Optimization of process parameters: Through a large number of experiments and simulations, the various parameters of the winding molding process, such as winding speed, temperature, humidity, etc., are optimized. These parameters will affect the winding effect and tension stability of the fiber. For example, in processes such as autoclaves and RTM, the control of temperature and pressure has an important influence on the curing and performance of the fiber. When producing composite products, a variety of technologies such as autoclaves and RTM are used, and strict quality inspections are carried out at each stage, which helps to ensure the stability of process parameters and the consistency of product quality, thereby providing good process guarantees for the precise control of fiber winding angles and tension.

Quality inspection and feedback: Relying on advanced inspection equipment, such as laser diameter gauges, electronic universal testing machines, etc., the quality of the carbon fiber special-shaped parts after winding is inspected. The inspection content includes the winding angle of the fiber, the uniformity of the tension, the mechanical properties of the special-shaped parts, etc. According to the test results, timely feedback and adjustment of process parameters and control strategies are made to continuously optimize the production process. Jiangyin Dongli New Materials Technology Co., Ltd. strictly implements the quality control system during the production process to ensure that each product meets industry standards. This strict control of quality helps to achieve precise control of the fiber winding angle and tension, thereby meeting the mechanical performance requirements of different parts.

English

English

中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt