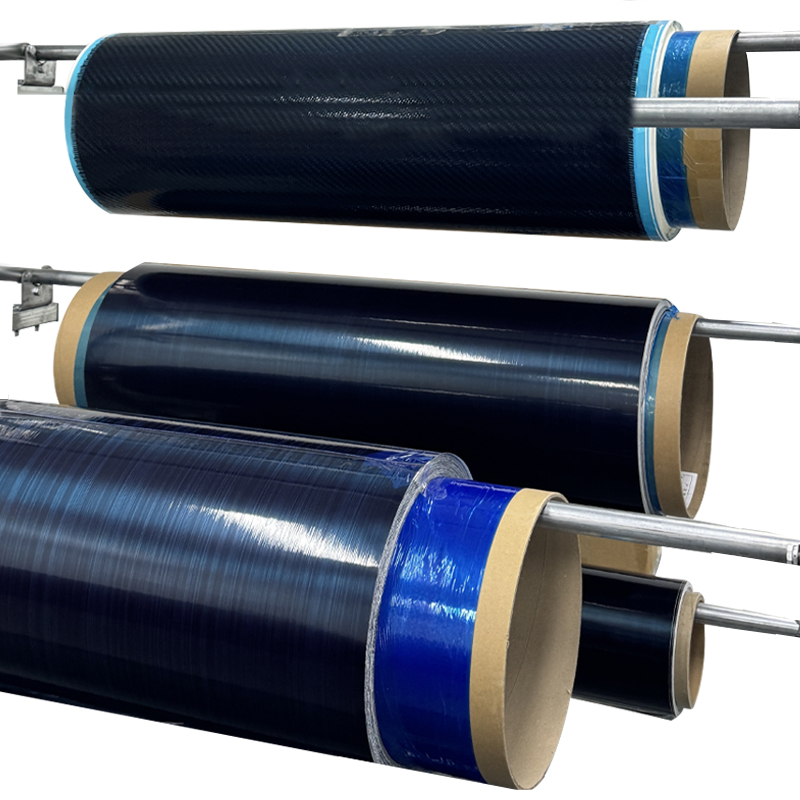

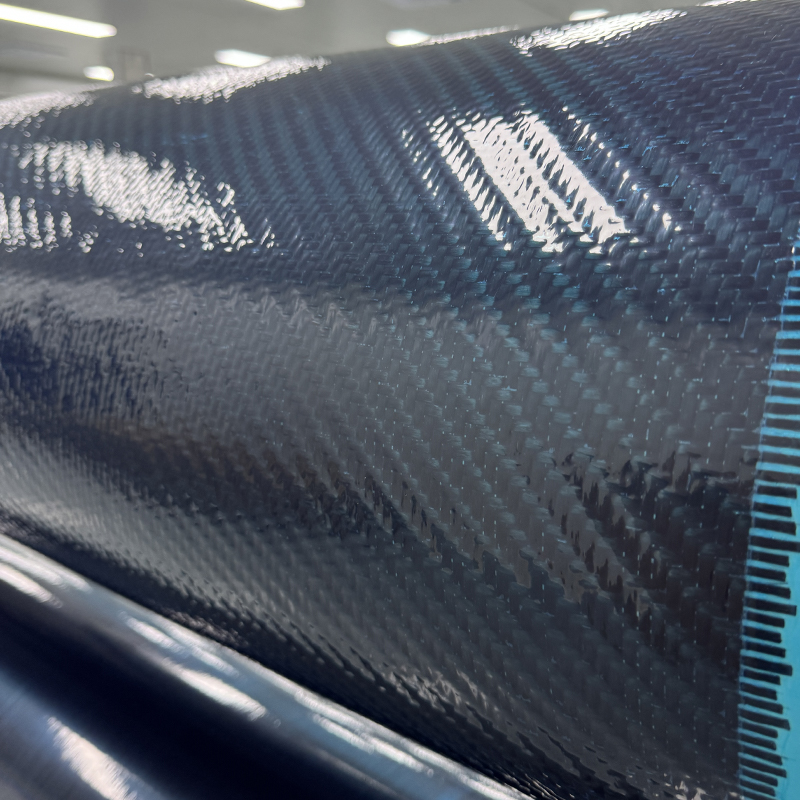

Currently, 70% of advanced composite products are made of prepregs that are stacked and cured. Prepregs are semi-finished products that are stored and prepared after fibers or fabrics are impregnated with resin matrix under strictly controlled conditions and then processed through a certain process. The role of the resin is to orient and position the fibers and bond them together; it also transmits stress during the product's stress process.

In the high-precision world of advanced composites, carbon epoxy prepreg represents the pinnacle of material efficiency, combining structural reinforcement with a pre-catalyzed resin system. However, the reactive nature ...

READ MORE English

English  中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt