UV resistance of Aramid Fiber

Ultraviolet (UV) radiation is a potential threat to most materials. Prolonged exposure to UV rays can lead to material degradation, such as color fading, strength loss, and structural damage. For most synthetic fibers, long-term exposure to UV rays often leads to material degradation, which especially affects their service life in outdoor environments.

However, Aramid Fiber, especially Para-Aramid (such as Aramid 1414) and Meta-Aramid (such as Aramid 1313), has excellent UV resistance. The aromatic ring and nitrogen elements in its molecular structure provide additional stability, making aramid fiber have strong absorption and reflection capabilities for UV rays. Especially Meta-Aramid fiber, its high temperature resistance and UV resistance make it the first choice for outdoor high-strength materials.

According to research, the decline in mechanical properties of Meta-Aramid fiber when exposed to UV rays for a long time is much lower than that of other common synthetic fibers such as polyester and nylon. This allows aramid fabrics to provide a long service life in fire-resistant clothing, military equipment and building materials, and is not easily damaged by ultraviolet exposure.

Chemical corrosion resistance of Aramid Fiber

In addition to ultraviolet rays, chemical corrosion is also one of the key factors restricting the long-term use of many materials. Many industrial applications, such as chemical processing plants, mining and petrochemical industries, require materials to maintain stable performance in highly corrosive environments. Aramid fibers also show excellent performance in this regard.

Unlike most polyester and nylon materials, aramid fibers are highly resistant to a variety of common chemicals. Meta-Aramid fibers have good corrosion resistance to acidic solutions, oxidants and some solvents, and can resist the damage of these substances to the fiber structure to a certain extent. Para-Aramid fibers, due to the special nature of their molecular structure, also show strong resistance to a variety of organic solvents, oils and acid-base solutions.

For example, the application of Aramid fabrics in the petrochemical industry often needs to face environments containing corrosive chemicals. Compared with ordinary fibers, the superior corrosion resistance of aramid fiber ensures its long-term stable use in these harsh environments. Especially in the manufacture of protective clothing and chemical protection equipment, aramid fiber can effectively avoid the damage to the fabric caused by chemicals.

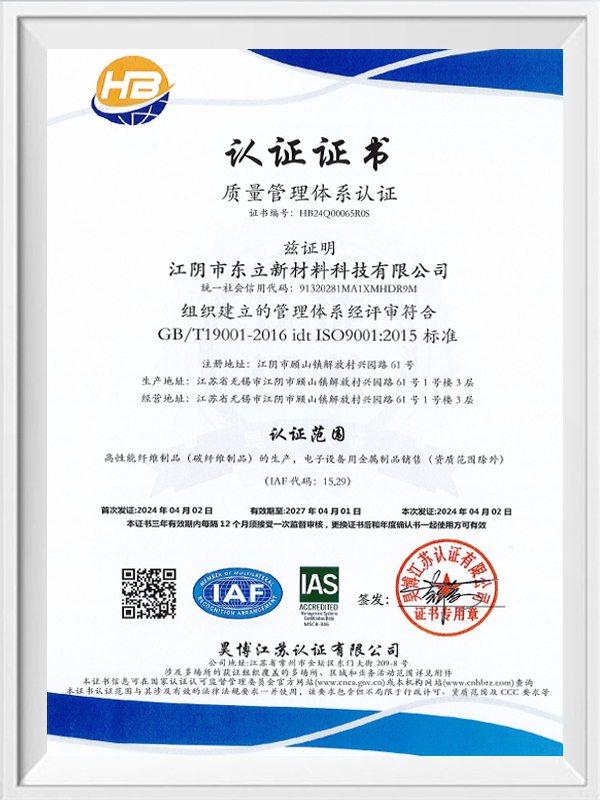

Jiangyin Dongli New Materials Technology Co., Ltd. is particularly outstanding in technological innovation in this field. As an enterprise integrating material innovation and engineering technology, Dongli New Materials uses high-performance fiber weaving, prepreg process and composite product production technology through precise process flow, which is widely used in the research and development and manufacturing of aerospace, automotive and sports equipment. The company improves the corrosion resistance of materials through the preparation of high-performance fiber composite materials, making its products show excellent durability in highly corrosive environments.

Due to its excellent UV resistance and chemical corrosion resistance, Aramid Fiber Woven Fabric has found important applications in many industries that require weather resistance and corrosion resistance. Fireproof clothing, aerospace, military equipment, automotive industry and other fields are actively using this high-performance material.

In the field of protective clothing, aramid fabric has become an important protective material due to its high temperature resistance, fire resistance, and UV resistance. It can not only effectively block ultraviolet rays, but also provide adequate protection when encountering fire sources to ensure the safety of the wearer. In the field of aerospace, due to its excellent UV resistance, Aramid Fiber is widely used in spacecraft external materials such as space suits and spacecraft shells. These materials can withstand solar radiation, climate change, and high-intensity ultraviolet radiation to ensure the service life of aerospace equipment in space.

In addition, in the chemical industry, Aramid Fiber Woven Fabric is often used in chemical protective clothing, filter materials, and other equipment involving chemical corrosion due to its excellent tolerance to acids, alkalis, and solvents. These applications fully demonstrate the reliability and stability of aramid fabrics in harsh environments.

English

English

中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt