How Epoxy Carbon Fiber Prepreg Becomes a Must-Have Material for High-Performance Sports Equipment

High Strength and Lightweight: Key Requirements for Sports Equipment

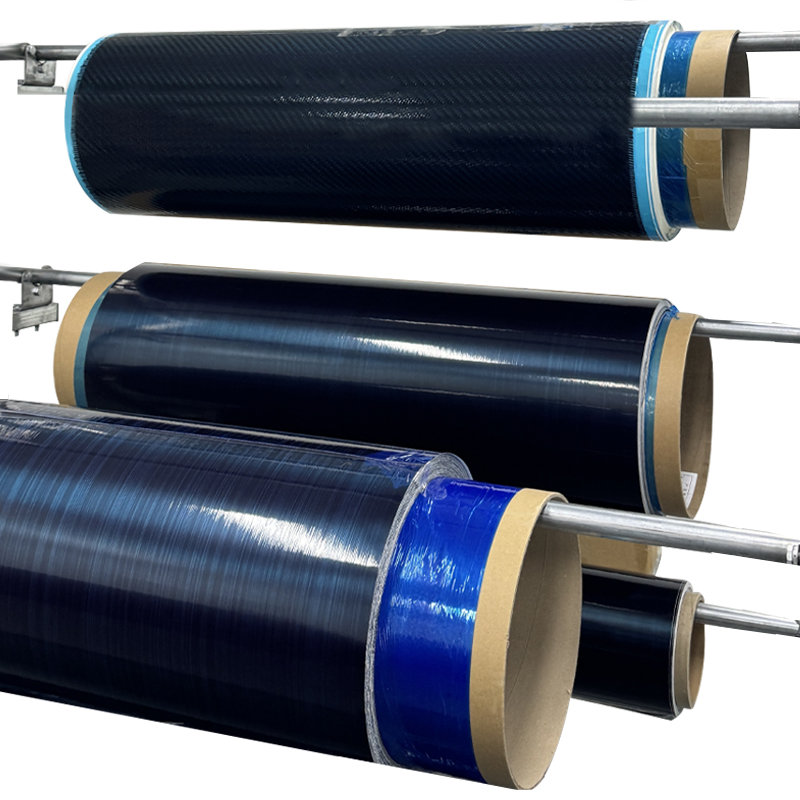

In the design of sports equipment, the balance between strength and weight is crucial. For some extreme sports, athletes need equipment that is both extremely strong and rigid, while remaining extremely light. For example, golf clubs, skis, etc. require materials that can achieve the best balance between strength and lightness. Traditional metal materials often cannot meet this requirement due to their heavy weight. Epoxy Carbon Fiber Prepreg, due to its high strength characteristics of carbon fiber, can provide extremely high strength and rigidity while maintaining extremely low weight. By reducing the weight of the equipment, athletes can operate more flexibly and improve their performance.

Durability and Corrosion Resistance: Improving the Service Life of Sports Equipment

Sports equipment is often exposed to various extreme environmental conditions, including high humidity, low temperature, strong ultraviolet radiation, etc., which places extremely high demands on the durability and corrosion resistance of the equipment. Especially in the marine environment, salt water, ultraviolet rays and changing temperatures are particularly harmful to materials. Therefore, corrosion resistance and UV resistance have become important factors that must be considered when selecting materials for sports equipment. Epoxy Carbon Fiber Prepreg has shown unique advantages in this regard. It can be used for a long time in these harsh environments without being damaged. Compared with traditional metal materials, Epoxy Carbon Fiber Prepreg can maintain stable performance for a long time when facing moisture, seawater and chemical erosion, greatly extending the service life of sports equipment.

For example, sports equipment such as golf clubs often need to be used outdoors and exposed to rain and extreme weather conditions. Golf clubs made of Epoxy Carbon Fiber Prepreg can resist rain erosion and will not rust or deteriorate in performance. This material not only maintains the lightness and high strength of sports equipment, but also solves the problem that traditional materials are prone to corrosion in wet environments, allowing athletes to use equipment for a longer time.

In the field of sports equipment, Jiangyin Dongli New Materials Technology Co., Ltd. provides strong support for the production of golf clubs, skis, racing cars and other equipment through its innovative technology and high-performance composite materials. The application of Epoxy Carbon Fiber Prepreg enables these sports equipment to maintain excellent performance and durability when facing various complex environmental conditions. The company focuses on strict control of every link in the production process to ensure that every product can meet the highest quality standards, driving the sports equipment industry towards higher performance and longer service life.

Good formability: Adapt to complex design requirements

Epoxy Carbon Fiber Prepreg not only has high strength and durability, but also has good formability. This makes it an ideal material for high-performance sports equipment, especially for parts that require complex geometries and precise dimensions. Through modern composite molding technology, carbon fiber prepreg can be precisely processed into complex shapes during the molding process to meet the diverse needs of sports equipment for appearance, structure and function. For example, in racing cars, carbon fiber can be precisely molded into aerodynamic body parts to reduce wind resistance and increase racing speed; in the manufacture of snowboards, the formability of carbon fiber materials allows manufacturers to customize the design of snowboards according to the needs of different athletes, improving comfort and performance.

Excellent fatigue strength: Adapt to high-intensity sports

Many high-performance sports equipment need to withstand long-term high-intensity use, which requires materials to have excellent fatigue strength. Epoxy Carbon Fiber Prepreg excels in this regard. The anti-fatigue properties of carbon fiber materials enable sports equipment to withstand long-term repeated use without easily breaking or deforming. For example, the frame of a racing car is subjected to frequent stress and impact under long-term high-speed movement. By using Epoxy Carbon Fiber Prepreg, the racing car frame can maintain high stability and reliability under high-intensity use conditions and is not easily damaged.

Energy saving and environmental protection: promoting the green sports industry

With the improvement of environmental awareness, the sports equipment industry has gradually paid attention to the environmental protection of materials. In the production process of Epoxy Carbon Fiber Prepreg, compared with traditional metal materials, its production energy consumption is lower and does not produce a large amount of pollution emissions. In addition, the high strength and lightweight characteristics of carbon fiber materials enable the energy efficiency of sports equipment to be improved, thereby reducing the impact on the environment. For example, bicycles and skis made of carbon fiber materials can reduce the energy consumption of athletes during exercise, improve exercise efficiency, and promote the development of the green sports industry.

Future trends: intelligence and personalized customization

With the development of intelligent manufacturing technology, future sports equipment will rely more on high-performance composite materials, especially in personalized customization. Epoxy Carbon Fiber Prepreg will be able to customize equipment that is more personalized according to the athlete's body shape, needs and preferences. Through advanced digital design and automated production technology, the production of sports equipment will become more sophisticated and efficient. In the future, sports equipment will not only have higher requirements in performance, but also meet more personalized needs in appearance and comfort.

English

English

中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt