Material selection

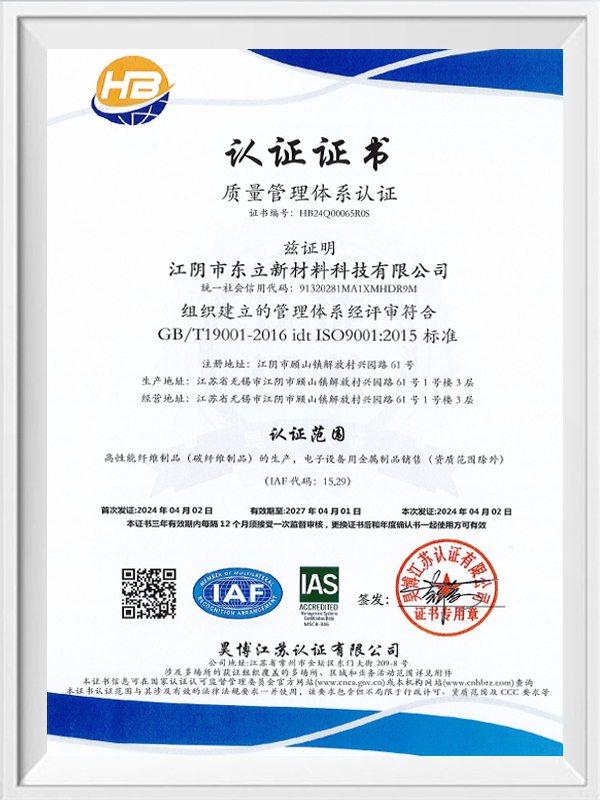

Carbon fiber type: For thin-walled and porous carbon fiber electronic equipment special-shaped parts, high-performance and high-strength carbon fiber should be selected, such as the carbon fiber in the special resin system customized by Jiangyin Dongli New Materials Technology Co., Ltd. for aerospace, automotive and industrial purposes. It has a high strength-to-weight ratio and excellent load-bearing capacity, which can meet the requirements of electronic equipment for strength and lightness of shaped parts. Different electronic equipment use environments and performance requirements may also need to consider the conductivity, thermal conductivity and other properties of carbon fiber to achieve better electromagnetic shielding, heat dissipation and other functions.

Matrix material: The selection of matrix material is crucial. According to the use environment and performance requirements of the special-shaped parts, a resin matrix with good fluidity, curing performance and good compatibility with carbon fiber should be selected. For example, in electronic equipment, the matrix material may need to have certain insulation properties and chemical corrosion resistance. The resin used in advanced prepreg technology can ensure uniform resin distribution, improve material strength, and facilitate processing, and can be used as a high-quality choice for the matrix material of such shaped parts.

Design and simulation

Structural design optimization: For special structures with thin walls and multiple holes, it is necessary to use advanced CAD/CAM technology for precise design. In the design process, the mechanical properties, electromagnetic properties and other requirements of special-shaped parts, as well as the influence of thin walls and porous structures on strength and stiffness should be fully considered. For example, through methods such as finite element analysis, the stress conditions of special-shaped parts under different working conditions are simulated, and the thin wall thickness distribution and the layout of porous structures are optimized to ensure that while meeting the lightweight requirements, they can withstand various stresses inside the electronic equipment and external impact vibrations.

Simulation verification: Use professional simulation software to simulate the production process, such as resin flow during resin transfer molding (RTM), temperature field and stress field distribution during curing, etc. Through simulation, potential problems can be discovered in advance, such as uneven resin filling, deformation caused by curing shrinkage, etc., and the process parameters can be optimized and adjusted to reduce the trial and error costs in actual production and improve production efficiency and product quality.

Manufacturing process

Prepreg preparation: Use advanced prepreg technology to ensure that the carbon fiber is fully impregnated with the resin and the resin is evenly distributed. For thin-walled structures, the thickness and glue content of the prepreg must be strictly controlled to ensure that the wall thickness of the special-shaped parts can be accurately controlled during the molding process. Tension control systems and intelligent looms can produce fabrics with good uniformity and density, providing a basis for the preparation of high-quality prepregs. In the process of prepreg preparation, it is also necessary to design a suitable fiber laying method according to the characteristics of the porous structure to avoid fiber accumulation or looseness around the holes, which affects the performance of the special-shaped parts.

Molding process

RTM process: For carbon fiber electronic equipment special-shaped parts with thin walls and porous structures, RTM process is a commonly used molding method. During the RTM process, the injection pressure, speed and temperature of the resin must be accurately controlled to ensure that the resin can evenly fill the mold cavity, especially in thin-walled and porous areas. It is necessary to select a suitable mold structure and ventilation system to facilitate the discharge of air and excess resin in the mold to avoid defects such as pores and lack of glue. Precision molding technology from RTM to hot pressing curing can ensure reliable mechanical properties and smooth surface effects, meeting the requirements of electronic equipment for the appearance and performance of special-shaped parts.

Hot Pressing: Hot press forming is suitable for some thin-walled and porous special-shaped parts with high requirements for dimensional accuracy and surface quality. In the hot press forming process, reasonable hot press process parameters such as temperature, pressure and holding time should be formulated according to the structural characteristics and material properties of the special-shaped parts. For thin-walled structures, excessive pressure should be prevented from causing excessive thinning of the wall thickness; for porous structures, attention should be paid to avoiding deformation or blockage of the holes during the hot press process. Jiangyin Dongli New Materials Technology Co., Ltd.'s autoclave and other equipment can provide precise temperature and pressure control to meet the hot press forming needs of special-shaped parts with different structural requirements.

Other processes: In addition to RTM and hot press forming, vacuum infusion, manual laying and other processes can also be selected according to specific circumstances. For example, for some thin-walled and porous special-shaped parts with complex shapes and small batches, manual laying combined with vacuum infusion process can better achieve personalized customization. In the manual laying process, the operator must have rich experience to ensure that the carbon fiber fabric is laid flat and tight, especially in thin-walled and porous parts, to ensure the continuity and uniformity of the fiber.

Quality inspection

Appearance inspection: Use optical inspection equipment, such as industrial cameras and microscopes, to conduct detailed inspections on the appearance of special-shaped parts, focusing on whether there are cracks, bubbles, glue deficiency and other defects in thin-walled parts, whether the porous structure is clear and regular, and whether the pore size and hole distribution meet the design requirements. For electronic equipment special-shaped parts with high surface quality requirements, it is also necessary to test indicators such as surface roughness and glossiness.

Dimensional accuracy inspection: Use precision measuring equipment such as three-coordinate measuring machines to measure the key dimensions of special-shaped parts, including thin-wall thickness, porous position and size, etc., to ensure that the dimensional deviation is within the tolerance range required by the design. For electronic equipment special-shaped parts with high precision requirements, the control of dimensional accuracy is particularly important, which directly affects the assembly accuracy with other components and the overall performance of the equipment.

Internal quality inspection: Use non-destructive testing technologies such as ultrasonic testing and X-ray testing to detect the fiber distribution, resin curing and internal defects such as delamination and inclusions inside the special-shaped parts. These detection methods can comprehensively evaluate the internal quality of special-shaped parts without destroying them, timely discover potential quality problems, and ensure product reliability.

Post-processing process

Surface treatment: In order to improve the surface performance and appearance quality of special-shaped parts, surface treatment is required. For example, grinding, polishing and other processes are used to make the thin-walled surface smoother, reduce surface roughness and improve aesthetics. For porous structures, a protective film can be formed on the surface of the hole wall by chemical plating, electroplating and other methods to improve its corrosion resistance and wear resistance.

Assembly and debugging: According to the overall design requirements of electronic equipment, carbon fiber special-shaped parts are assembled and debugged. During the assembly process, care should be taken to avoid damage to thin walls and porous structures, and ensure that the connection between special-shaped parts and other components is firm and well sealed. The assembled special-shaped parts should be tested and debugged for performance, such as electromagnetic shielding performance test, heat dissipation performance test, etc., to ensure that they meet the actual use requirements of electronic equipment.

The production process requirements of carbon fiber electronic equipment special-shaped parts with special structures such as thin walls and porous structures are strict and complex, and require precise control and optimization of various links from material selection, design and simulation, manufacturing process, quality inspection to post-processing process. Jiangyin Dongli New Materials Technology Co., Ltd. has rich experience and advanced technology in the field of high-performance fiber composite materials. Its full-process controlled production model, professional R&D team, and advanced equipment and processes provide a strong guarantee for the production of high-quality carbon fiber electronic equipment special-shaped parts, which can meet the electronic equipment industry's growing demand for high performance, high precision and customization of special-shaped parts.

English

English

中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt