In the precision-driven field of aerospace manufacturing, the performance of composite structures is fundamentally dictated by the constituent ratio within the carbon epoxy prepreg. Achieving the ideal balance between the carbon fiber reinforcement and the epoxy resin matrix is not merely a manufacturing preference but a critical engineering requirement. Jiangyin Dongli New Materials Technology Co., Ltd. operates at the forefront of this sector, utilizing a 32,000-square-meter industrial complex with 100,000-grade purification zones to ensure material purity. As a comprehensive manufacturer, we integrate material innovation with full-process control, covering weaving, prepreg production, and advanced molding techniques like RTM and autoclave processing to serve the most demanding aerospace applications.

The Critical Role of Resin Content in Aerospace Structural Weight

The primary driver for using high TG carbon epoxy prepreg for aerospace is the pursuit of mass reduction without compromising safety. Resin serves to protect fibers and transfer loads, but excess resin adds "dead weight" that does not contribute to the primary tensile load-bearing capacity. According to the 2024-2025 Global Composite Market Analysis, optimizing resin content to within a 33%-42% weight range is essential for next-generation narrow-body aircraft efficiency targets. Excessively high resin content increases the density of the final laminate, whereas a controlled, lower resin ratio maximizes the specific strength of the component.

Source: Lucintel: Global Composites Market Trends and Forecast 2024-2030

Weight Efficiency Comparison: High Resin vs. Optimized Resin Content

While high resin content simplifies the manufacturing process by ensuring better "wet-out," it significantly penalizes the structural weight efficiency. In contrast, optimized resin content provides a higher fiber volume fraction, which is the gold standard for aerospace engineering.

| Metric | High Resin Content (>45%) | Optimized Resin Content (35%-38%) |

| Specific Gravity | Higher; increased parasitic weight. | Lower; ideal for flight structures. |

| Load Distribution | Inter-laminar dominated; lower fiber density. | Fiber dominated; maximum axial load capacity. |

| Production Cost | Lower complexity in lay-up. | Requires precision control (Autoclave). |

Tensile Strength and the Critical Fiber Volume Fraction

The tensile strength of a carbon epoxy prepreg component is directly proportional to the number of fibers aligned with the load path. However, a "resin-starved" condition is equally dangerous, as it leads to dry spots and delamination. Engineers often refer to unidirectional carbon epoxy prepreg technical data to determine the theoretical maximum fiber volume fraction (Vf), which typically peaks around 60%-65% for aerospace grades. Beyond this point, there is insufficient resin to bind the fibers, leading to a sharp drop in transverse strength and durability.

Resin-Rich Zones vs. Resin-Starved Defect Impact

Resin-rich areas tend to be brittle and prone to micro-cracking under thermal cycling, while resin-starved areas suffer from poor interfacial bonding. Both extremes compromise the integrity of the aerospace assembly.

| Condition | Resin-Rich Areas | Resin-Starved Areas |

| Failure Mode | Brittle matrix cracking. | Fiber debonding and delamination. |

| Impact on Tensile Strength | Marginal reduction; weight penalty. | Significant reduction; structural risk. |

| Appearance | Glossy, thick surface. | Dull, "dry" fiber texture visible. |

Advanced Manufacturing: The Autoclave Advantage

To achieve the high-precision ratios required for flight, the carbon epoxy prepreg autoclave curing process is the preferred industry method. The autoclave applies simultaneous heat and external pressure, forcing out excess resin and trapped air (voids). Recent data from 2024 aerospace material standards suggests that void content must be maintained below 1% for primary structures, a feat only achievable through controlled prepreg processes and pressurized curing.

Source: SAE International: AMS3894 Carbon Fiber Epoxy Resin Preimpregnated Materials

Why Choose Dongli New Materials?

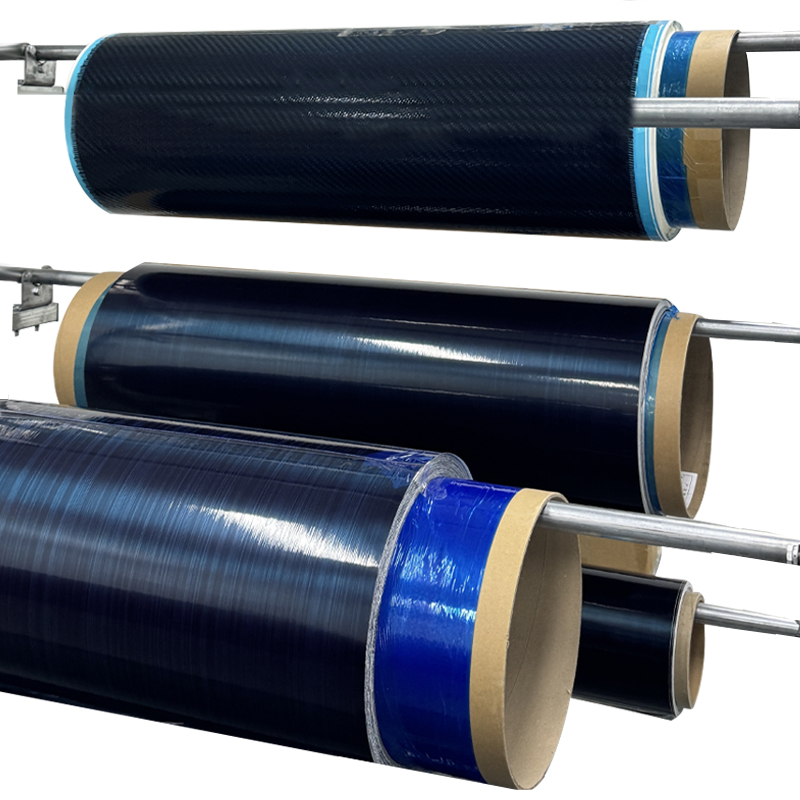

As one of the leading wholesale carbon epoxy prepreg suppliers China, Jiangyin Dongli provides a one-stop factory solution. Our facilities feature climate-regulated workshops and 100,000-grade purification zones to ensure that every roll of prepreg, including low temperature curing carbon epoxy prepreg, meets the highest purity standards. We offer full process control—from weaving high-performance fiber fabrics to the final composite product utilizing RTM, PCM, or autoclave technology.

Conclusion: Strategic Selection for Aerospace Excellence

The resin-to-fiber ratio is the "DNA" of a composite part. By meticulously controlling this ratio through advanced carbon epoxy prepreg production and curing, manufacturers can achieve the high strength-to-weight ratios that aerospace engineering demands. Whether you require unidirectional carbon epoxy prepreg technical data for structural modeling or are seeking wholesale carbon epoxy prepreg suppliers China for large-scale production, Dongli New Materials provides the engineering expertise and precision environment to ensure your success.

Frequently Asked Questions (FAQ)

- What is the standard resin content for aerospace prepregs? Most aerospace components utilize a resin weight of 33% to 38%, which translates to a fiber volume fraction of approximately 60%.

- How does the carbon epoxy prepreg autoclave curing process affect the final ratio? The autoclave uses pressure to "bleed" out calculated amounts of excess resin, ensuring a consolidated, low-void laminate.

- Can low temperature curing carbon epoxy prepreg maintain high strength? Yes, modern low-temp resins are engineered to provide excellent mechanical properties while reducing the thermal stresses on large-scale tooling.

- What is the benefit of high TG carbon epoxy prepreg for aerospace? A high Glass Transition temperature ensures the component maintains its structural stiffness at the elevated temperatures encountered during high-speed flight or near engine bays.

- Where can I find unidirectional carbon epoxy prepreg technical data? Jiangyin Dongli provides comprehensive data sheets for all our fabric types, covering tensile modulus, strength, and curing cycles.

English

English  中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt