How will Carbon Fiber Prepreg revolutionize the aviation manufacturing industry in 2025?

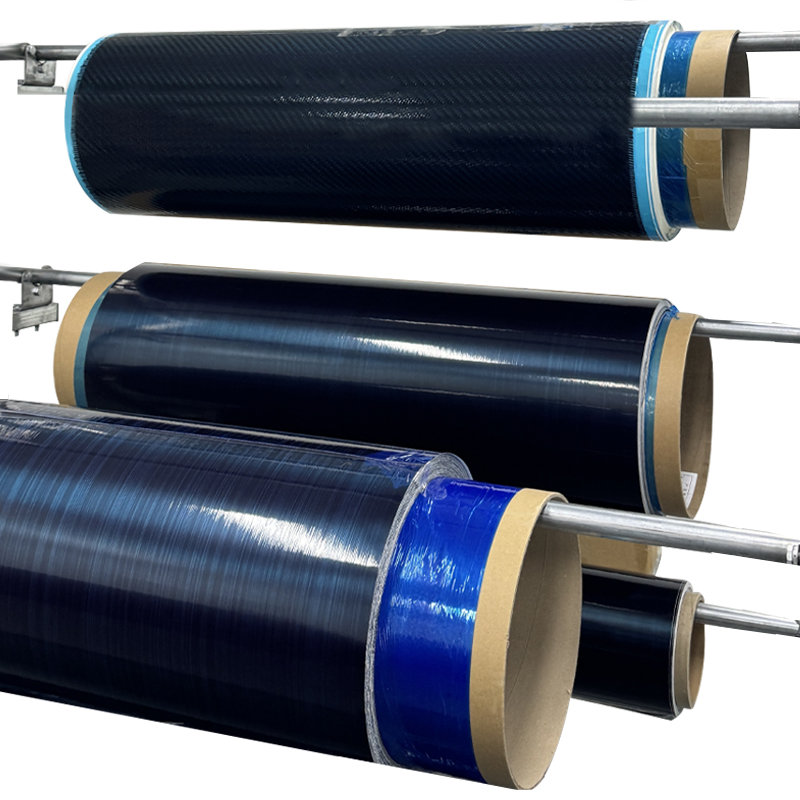

Carbon Fiber Prepreg is a composite material pre-impregnated with carbon fiber and resin (usually epoxy resin), which has extremely high strength and rigidity while maintaining a relatively light weight. This makes it an ideal material for aviation manufacturing, especially in parts that need to improve structural strength and reduce weight. Compared with traditional metal materials, carbon fiber composites are lighter in weight but have higher strength and rigidity, making them ideal for lightweight and high performance in aviation manufacturing.

Improve production efficiency and reduce labor costs

In the traditional aviation manufacturing process, manual operations take up a lot of time, and improving production efficiency has always been the core goal of the industry. The automated laying technology and efficient curing process used by Carbon Fiber Prepreg can greatly improve production efficiency, reduce manual intervention, shorten production cycles, and significantly reduce labor costs. The automated process not only improves production accuracy, but also makes the molding process of composite materials more stable and consistent, thereby ensuring the quality and performance of each component.

Durability and corrosion resistance of Carbon Fiber Prepreg

The durability and corrosion resistance of Carbon Fiber Prepreg are one of its key advantages in aviation manufacturing. Modern aircraft components need to operate for a long time under extreme temperature, humidity and pressure conditions, and carbon fiber composite materials can maintain stable performance in these environments. Its excellent fatigue resistance and corrosion resistance enable aviation components to work stably for a long time in more severe environments, thereby reducing the frequency of maintenance and replacement, and greatly reducing operating costs. The high strength and durability of Carbon Fiber Prepreg help improve the overall reliability of aircraft, ensuring that airlines can reduce maintenance costs and downtime.

Contribution of Carbon Fiber Prepreg to Environmental Protection

As global environmental protection requirements continue to increase, aviation manufacturers are constantly seeking ways to reduce carbon emissions and resource consumption during design and production. The use of Carbon Fiber Prepreg helps reduce the weight of aircraft, thereby improving fuel efficiency, reducing carbon emissions, and promoting a more environmentally friendly aviation industry. Lightweight design not only reduces energy consumption, but also meets strict environmental regulations while enhancing the competitiveness of airlines in the global green aviation initiative.

Enterprise Contribution and Technological Innovation

Enterprises like Jiangyin Dongli New Materials Technology Co., Ltd. play an important role in this transformation. Dongli focuses on the research and development and production of high-performance fiber composite materials, with a precisely controlled production environment, including a climate-controlled workshop and a Class 100,000 cleanroom area. The company combines material innovation with engineering technology to provide solutions for technical fields such as aerospace, automotive manufacturing and sports equipment. Through continuous technological innovation and precision manufacturing processes, Dongli has greatly improved the production efficiency and performance of Carbon Fiber Prepreg, driving the growth of demand for carbon fiber composites in the aviation field.

Outlook for 2025: Widespread Application of Carbon Fiber Prepreg

As 2025 approaches, the application of Carbon Fiber Prepreg in the aerospace industry will usher in a more widespread promotion. With the continuous advancement of automation technology and materials science, Carbon Fiber Prepreg will be widely used in the production of more aircraft components, including important structural parts such as aircraft fuselages, airfoils, and engine components. It is expected that by 2025, Carbon Fiber Prepreg will become one of the core materials for aircraft design and production, further promoting lightweighting, improving fuel efficiency and enhancing overall performance.

English

English

中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt