High-performance fiber composites have become an indispensable key material in the aerospace field due to their excellent properties such as light weight, high strength and corrosion resistance. As aircraft and spacecraft develop towards lightweight, high performance and long life, the application scope of such materials continues to expand, and technological innovations continue to emerge. The following is a systematic analysis of its main applications and innovation directions:

I. Core application areas

Aircraft structural parts

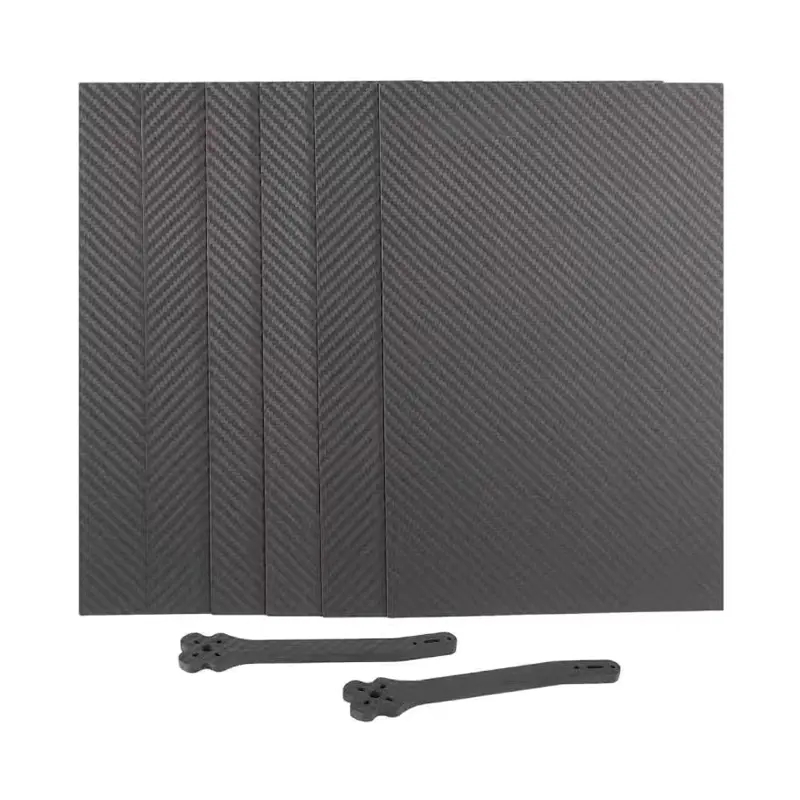

Fuse and wings: The large-scale application of carbon fiber reinforced composites (CFRP) in Boeing 787 (50%) and Airbus A350 (53%) significantly reduces weight (20%-30%) and reduces fuel consumption.

Ear and flaps: The use of thermosetting composite materials (such as epoxy resin matrix) improves fatigue resistance and reduces the number of metal connectors.

Spacecraft components

Rocket shells and fuel tanks: Aramid fibers (such as Kevlar) and carbon fiber hybrid composites are used to reduce launch weight while bearing extreme mechanical loads.

Satellite structure: High modulus carbon fiber/cyanate ester resin system meets dimensional stability requirements and adapts to the thermal cycle environment of space.

Engine components

Fan blades and casings: Ceramic matrix composites (CMC) are used in GE Aviation LEAP engines, which can withstand high temperatures of 1600°C and replace traditional nickel-based alloys.

Nozzle thermal protection: Carbon/carbon composites (C/C) are used in rocket engine nozzles and have excellent ablation resistance.

2. Technological innovation direction

Breakthrough in material system

New fiber: PBO fiber (Zylon) has a strength of 5.8GPa and is used for high-stress components; graphene-modified fibers improve electrical/thermal conductivity.

Smart composites: Embedded fiber sensors or carbon nanotubes to achieve structural health monitoring (SHM), such as Airbus' "Smart Wing" project.

Manufacturing process upgrade

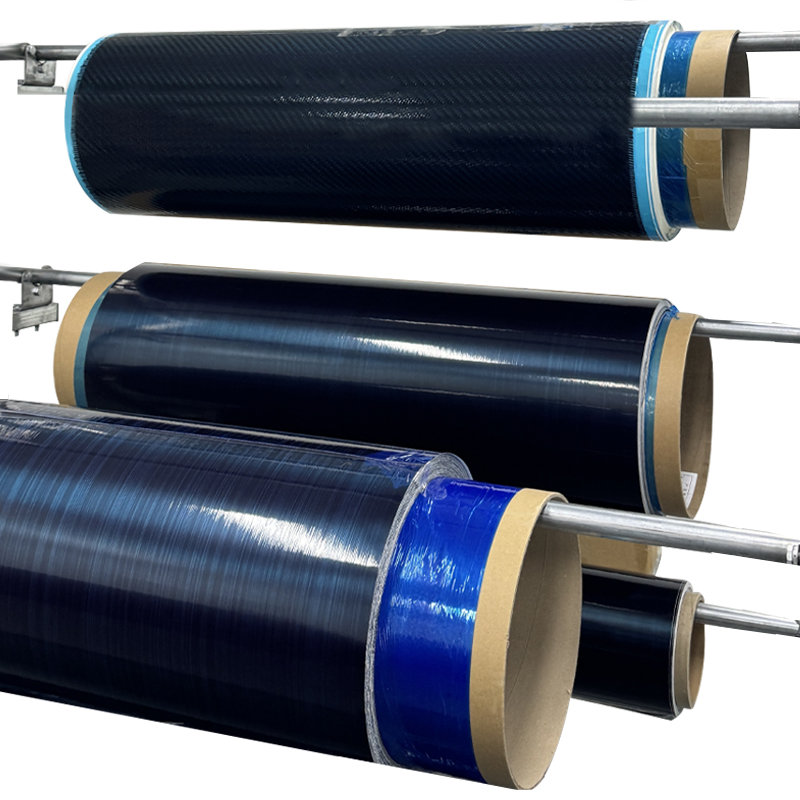

Automated molding technology: Automatic fiber placement (AFP) and fiber placement (ATL) technologies improve the molding efficiency of large components (such as the integral molding of Boeing 777X wings).

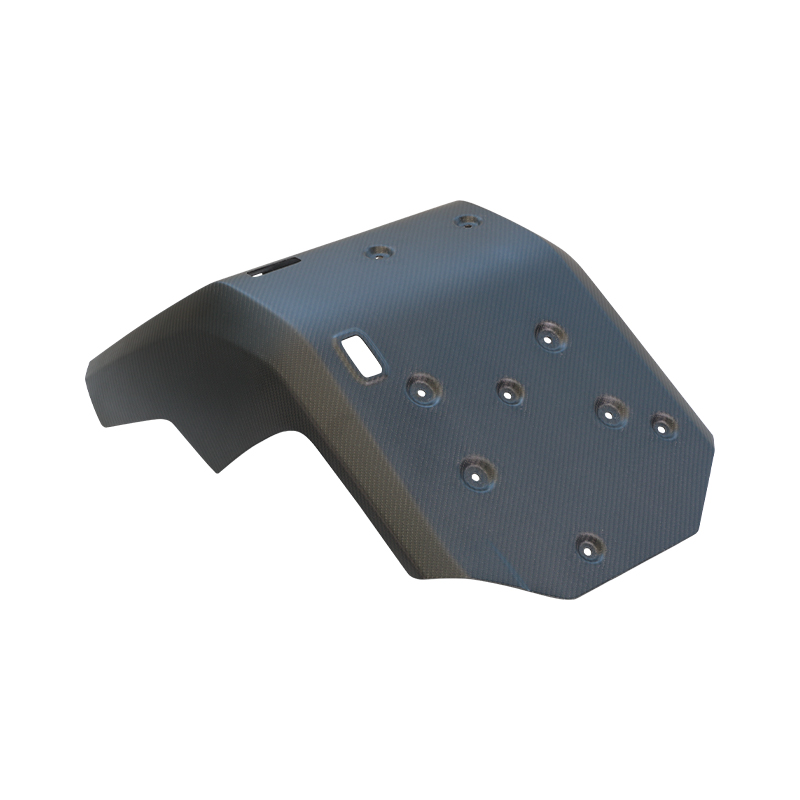

Additive manufacturing: 3D printing of chopped fiber reinforced thermoplastic composites for rapid molding of complex special-shaped parts.

Multifunctional integrated design

Structure-function integration: conductive composite materials are used for lightning protection (such as the leading edge of the Boeing 787 wing); wave-transparent composite materials are used for radomes.

Environmentally friendly and recyclable: The recycling technology of thermoplastic composite materials (such as PEEK-based) meets the EU aviation emission reduction goals.

English

English

中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt